Add reliability to your lubrication program with dependable, automatic

re-greasing

Incorrect or inadequate lubrication results in equipment damage that can lead to breakdown. In many cases, single point lubricators are the solution to this problem. With Xport® Single Point Lubricators filled with LE lubricants, you can deliver the right lubricant, in the right amount, to the right place, at the right time – 24/7. Xport Single Point Lubricators filled with LE lubricants help eliminate costly manual lubrication. They literally pay for themselves by reducing downtime, part replacements, labor costs, and lubricant and machine contamination issues – all while increasing the safety of your operation.

Xport® Single Point Lubricators

- Ensure critical applications receive lubricant 24/7

- Eliminate application of the wrong lubricant, avoiding costly cross-contamination issues

- Eliminate under- or over-application of lubricant

- Increase safety with installation in hard-to-access locations

- Keep dust and moisture out of the equipment with hermetically sealed lubrication points

Xport® Single Point Lubricators are rugged, durable and easy to install. They are perfect for mining operations, steel manufacturers, power plants, water and wastewater treatment facilities, cement plants, food processing plants, and manufacturing facilities of all types. Xport SPLs are installed on millions of roller and slide bearings, blowers and fans, chains, pumps, presses, motors, open gears, and conveyors across the globe.

Xport Electromechanical Lubricators

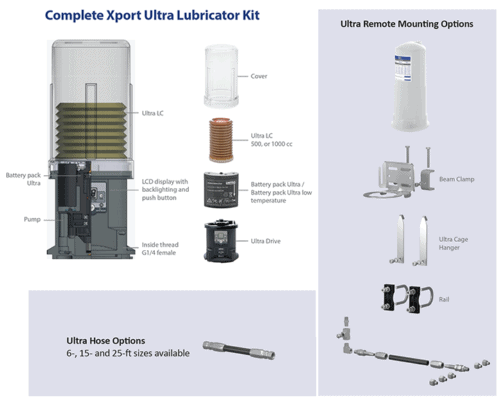

Xport® Ultra Lubricator

Xport® Ultra Lubricator

The Xport® Ultra is a fully automatic lubrication system, independent of temperature and counter pressure with a very precise discharge. With two cartridge sizes, pressure build-up to 725 psi / 50 bar, options of weekly and monthly time settings, the Xport Ultra is an extremely versatile and capable lubrication system suited to a wide range of applications which demand high lubrication rates and where long remote grease lines are necessary to ensure safe access.

Typical Applications: Drag conveyors, shaker screens, rotary kilns and belt conveyors

Typical Industries: Environmental technology, food industry, oil and gas production, paper industry, pharmaceutical industry

Ultra Lubricant Cartridge

After the lubricant is discharged from the Xport Ultra Unit, you do not have to order another complete unit. Instead, just order an Ultra LC (includes lubricant cartridge with Standard Alkaline battery or Low Temperature Lithium Battery) and reuse the Ultra Drive Unit.

Xport® Star Vario & Star Vario Bluetooth Lubricator

The Xport® Star Vario, now with Bluetooth capabilities, is an automatic single point lubricator that operates fully automatically, independent of temperature, and offers a precise discharge. It is ideal for applications that require precise lubricant metering and is a preferred system for electric motors requiring specific re-lubrication amounts. The system consists of an electrochemical drive unit; a lubrication cartridge (LC) with a volume of 60, 120, 250 or 500 cc (2.03, 4.06, 8.45 or 16.9 fl oz); and a battery pack. The desired discharge period and LC size can easily be selected with the setting button and are immediately visible in the LCD. The current operating status is indicated on the LCD and via LED signal lights (red/green) that are visible all around and from a distance. The unit is protected against dust and water jets when the individual parts are assembled correctly.

Typical Applications: Chains, electric motors, gear racks, open gears, roller and sliding bearings, shaft seals, sliding guides, spindles

Typical Industries: Environmental technology, food industry, oil and gas production, paper industry, pharmaceutical industry

Star Lubricant Cartridge

After the lubricant is discharged from the Star Vario unit, you do not have to order another complete unit. Instead, just order a Star LC (includes lubricant cartridge with installed battery) and reuse the Star Vario Drive Unit.

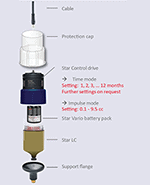

Xport® Star Control Lubricator

The Xport® Star Control automatic single point lubricator is ideal for applications that require precise lubricant metering, and it is a preferred system for electric motors with very specific re-lubrication amounts. The Star Control is supplied with external power via cable, and its operating status can be transmitted to a PLC via this connection. This system offers two operating modes – time and impulse – for more flexibility. In time mode, lubricant dispensing is dependent on operating hours.

In impulse mode, a precisely defined quantity is dispensed as soon as voltage is applied. The desired mode can be selected via the LCD. The Star Control consists of an electromechanical drive with LCD and a lubricant cartridge (LC) with lubricant volume of 60, 120 or 250 cc (2.03, 4.06 or 8.45 fl oz). The system discharges exact amounts independent of temperature and counter pressure. It is protected against dust and water jets when the individual parts are assembled correctly.

Typical Applications: Chains, electric motors, gear racks, open gears, roller and sliding bearings, shaft seals, sliding guides, spindles

Typical Industries: Mining, recycling industry, power plants, food industry, paper industry

Star Lubricant Cartridge

After the lubricant is discharged from the Star Control unit, you do not have to order another complete unit. Instead, just order a Star LC (includes lubricant cartridge with installed battery) and reuse the Star Control Drive Unit.

Xport® SPL Direct Mounting

Direct mounting of LE’s single-point lubricators is quick and easy. This installation method is recommended for …

- Lubrication points with minimal vibration and shock loading

- Safe, easy-to-reach lubrication points

Xport® SPL Remote Mounting

For many lubrication points, it is beneficial to install remote mount lubrication systems where they are safe to access while machinery is operating. Remote mounting is recommended if …

- It is necessary to remove protective guards or safety cages to access the lubrication point.

- Lube point is difficult or unsafe to access while equipment is running.

- Lube point is subject to severe vibration or high temperatures that could damage the lube system.

- Permits are required to access lubrication points when in confined spaces or when fall protection is required.

- Lube point is exposed to excessive amounts of water, process materials or impact from solid material.

If you cannot direct mount the Xport Single Point Lubricators, LE offers the following high-quality remote mounting options.

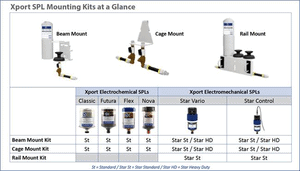

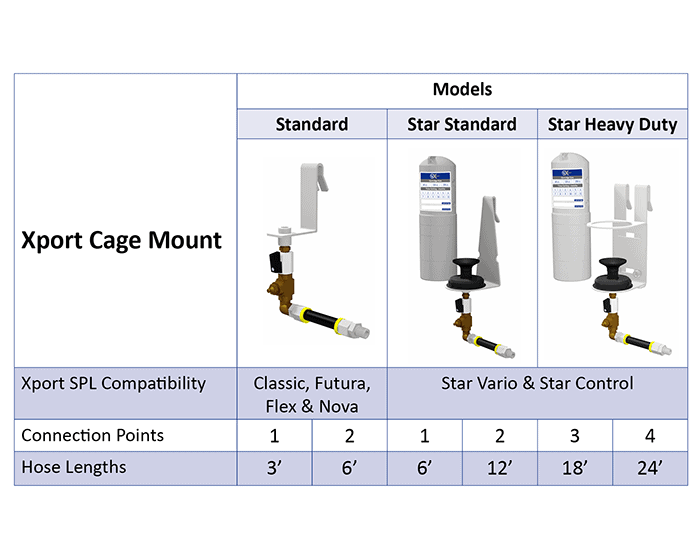

Xport® SPL Cage Mount Kits

- Xport Cage Mount Kit – Standard

- Xport Cage Mount Kit – Star Standard

- Xport Cage Mounts Kit – Star Heavy Duty

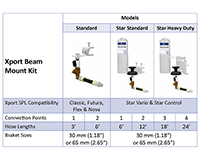

Xport® SPL Beam Mount Kits

- Xport Beam Mount Kit – Standard

- Xport Beam Mount Kit – Star Standard

- Xport Beam Mount Kit – Star Heavy Duty

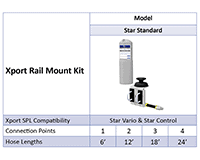

Xport® SPL Rail Mount Kit

Xport® Electrochemical Single Point Lubricators

Xport® Classic Lubricator

The Xport® Classic Lubricator is an automatic single point lubricator recommended for all applications with ambient temperatures of 0° to 40°C (32° to 104°F). Its reliable operating principle is based on an electrochemical reaction. The lubrication period is determined by color-coded activator screws. Depending on your application’s requirement, you may choose to discharge 120 cc (4.06 fl oz) in a period of 1, 3, 6 or 12 months. The activator screw generates a maximum pressure of 4 bar (58 psi), which moves the piston forward and continuously injects small lubricant amounts into the lubrication point.

Typical Applications: Chains, gear racks, open gears, roller & sliding bearings, shaft seals, sliding guides, spindles

Typical Industries: Automotive, mining, steel

Xport® Futura Lubricator

The Xport® Futura Lubricator is the ideal automatic single point lubricator for areas that must be kept hygienically clean or for harsh operating conditions that may lead to corrosion of metal lubricators or electronic systems. Due to its resistance to corrosion, the Flex unit is especially suited for applications in the food industry. Its reliable operating principle is based on an electrochemical reaction. The lubrication period is determined by color-coded activator screws. Depending on your application’s requirement, you may choose to discharge 120 cc (4.06 fl oz) in a period of 1, 3, 6 or 12 months. The activator screw generates a maximum pressure of 4 bar (58 psi), which moves the piston forward and continuously injects small lubricant amounts into the lubrication point.

Typical Applications: Blowers & fans, chains, conveyors, gear racks, open gears, roller & slider bearings, shaft seals, sliding guides, spindles

Typical Industries: Cement, chemical, food, mining, recycling

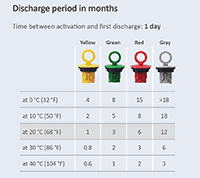

Classic and Futura activator selection

Both the Xport® Classic and Xport® Futura lubricators discharge lubricant based on an electrochemical reaction that is created after the activator screws have been placed in the units. Depending on your application’s requirement, you may choose to discharge 120cc in a period of 1, 3, 6 or 12 months (based on ambient temperature of 20°C (68°F)). The activator screw generates pressure that moves the piston forward and continuously injects small lubricant amounts into the lubrication point.

Choose the right color-coded activator screw (yellow, green, red or gray) for the desired discharge period, which varies with ambient temperature. See chart to help with selection.

Xport® Flex Lubricator

The Xport® Flex Lubricator is an automatic single point lubricator that can be used for all types of industries and challenging applications, including inside and outside in a wide range of temperatures. Excellent ingress protection ensures reliable lubrication even in extremely dusty and moist environments. Available in two convenient sizes – 60 and 125 cc (2.03 and 4.23 fl oz) – the Flex is especially suited for installation in tight and restricted areas. The discharge period is flexible and can be adjusted from 1 to 12 months.

How It Works

The Flex comes fully assembled and ready-to-use. Simply turn to the desired discharge period, and the system is activated. The electronically controlled chemical reaction will build up the pressure that is necessary to continually supply the lubrication point with fresh lubricant. If necessary, the discharge period can be adjusted even after activation. And, it can be switched off during longer non-operation periods.

Typical Applications: Electric motors, open gears, pumps, roller bearings, sliding bearings

Typical Industries: Food, mining, oil and gas, quarrying, refinery

Xport® Nova Lubricator

The Xport® Nova Lubricator is an automatic single point lubricator that can be used for all applications that are within a temperature range of -20° up to 60°C (-4° up to 140°F). The Nova unit is ideal for areas with considerable temperature variations (e.g., outside installations) or where intrinsic safety is a requirement (e.g., oil and gas industry). A discharge period of 1 to 12 months can be easily programmed by pushing the selection button on the Nova drive unit. A built-in temperature sensor periodically measures the ambient temperature, and the drive unit calculates the required gas generation based on this data. This ensures a continuous and controlled discharge. The Xport Nova consists of a reusable drive, a lubricant canister (LC) filled with 125 cc (4.23 fl oz) of grease or oil, and a protective cover.

Typical Applications: Chains, electric motors, gear racks, open gears, roller & slider bearings, shaft seals, sliding guides

Typical Industries: Cement, food, mining, oil and gas, power plants, recycling

Nova Lubricant Cartridge

After the lubricant is discharged from the Nova unit, you do not have to order another complete unit. Instead, just order the Xport Nova LC refill unit (includes lubricant cartridge with installed battery) and reuse the Nova Drive Unit.

Xport® SPL App

Application-oriented calculation tool for optimized lubrication

- Use app on mobile device or computer as platform for lubrication with Xport SPLs and LE grease.

- Calculates required lubricant amount and discharge settings for your lubrication system based on entry of existing operating conditions.

- Can easily be installed on all common iOS and Android mobile devices. Browser version is also available. *

*Download and use of software is free of charge. Online costs by your internet service provider must be paid by user.

Get Started Now!

Mobile Device

- Open app store on your device.

- In search bar, type “Xport SPL App” and then hit enter, select app and download to your phone.

- Follow the steps on your device, then you’ll be ready to begin using the Xport SPL App.

Computer

- For browser access, go to https://app.lelubricants.com “Takes a second to load”

- Follow the steps on your browser, then you’ll be ready to begin using the Xport SPL App.

LE offers full-service support for our Xport® Single Point Lubricators and other reliability solutions

In addition to onsite equipment assessment, consultation and service, LE provides the following customization and value-added options:

- Product recommendation, sizing and installation of single point lubricators

- Lubrication reliability training & education

LE is happy to offer industrial lubricant and reliability recommendations for a variety of industries and applications, and to provide product-specific data on all our items to help you make the right decision. To learn more about our enhanced lubricants and lubricant reliability products, please contact LE today.