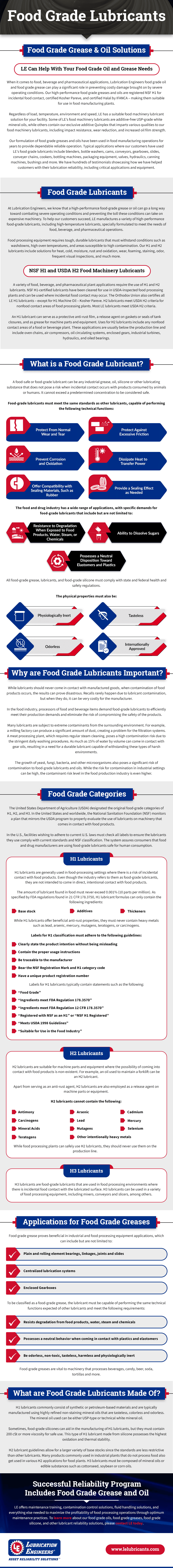

Food Grade Grease & Oil Solutions

LE can help with your food grade oil and food grade grease needs

When it comes to food, beverage and pharmaceutical applications, Lubrication Engineers food grade oil and food grade grease can play a significant role in preventing costly damage brought on by severe operating conditions. Our high-performance food grade greases and oils are registered NSF H1 for incidental food contact, certified Kosher Pareve, and certified Halal by IFANCA – making them suitable for use in food manufacturing plants.

Regardless of load, temperature, environment and speed, LE has a suitable food machinery lubricant solution for your facility. Some of LE’s food machinery lubricants are additive-free white mineral oils, while others contain our exclusive additive Quinplex that imparts various qualities to our food machinery lubricants, including impact resistance, wear reduction, and increased oil film strength.

Our formulation of food grade greases and oils have been used in food manufacturing operations for years to provide dependable reliable operation. Typical applications where our customers have used LE’s food grade lubricants include blenders, bottle washers, cams, conveyors, gearboxes, slides, conveyer chains, cookers, bottling machines, packaging equipment, valves, hydraulics, canning machines, bushings and more. We have hundreds of testimonials showcasing how we have helped customers with their lubrication reliability, including critical applications and equipment.

Food Grade Lubricants

At Lubrication Engineers, we know that a high-performance food-grade grease or oil can go a long way toward combating severe operating conditions and preventing the toll these conditions can take on expensive machinery. To help our customers succeed, LE manufactures a variety of high-performance food-grade lubricants, including high-temperature lubricants, specially formulated to meet the needs of food, beverage, and pharmaceutical operations.

Food processing equipment requires tough, durable lubricants that must withstand conditions such as washdowns, high oven temperatures, and areas susceptible to high contamination. Our H1 and H2 lubricants include solutions for heat, cold, moisture, rust and oxidation, wear, foaming, staining, odor, frequent visual inspections, and much more.

NSF H1 and USDA H2 Food Machinery Lubricants

A variety of food, beverage, and pharmaceutical plant applications require the use of H1 and H2 lubricants. NSF H1-certified lubricants have been cleared for use in USDA-inspected food processing plants and can be used where incidental food contact may occur. The Orthodox Union also certifies all LE H1 lubricants – except for H1 Machine Oil – Kosher Pareve. H2 lubricants meet USDA H2 criteria for nonfood contact areas of food processing plants. Most LE lubricants meet USDA H2 criteria.

An H1 lubricant can serve as a protective anti-rust film, a release agent on gaskets or seals of tank closures, and as grease for machine parts and equipment. Uses for H2 lubricants include any nonfood contact areas of a food or beverage plant. These applications are usually below the production line and include oven chains, air compressors, oil circulating systems, enclosed gears, industrial turbines, hydraulics, and oiled bearings.

What is a Food Grade Lubricant?

A food-safe or food-grade lubricant can be any industrial grease, oil, silicone or other lubricating substance that does not pose a risk when incidental contact occurs with products consumed by animals or humans. It cannot exceed a predetermined concentration to be considered safe.

Food-grade lubricants must meet the same standards as other lubricants, capable of performing the following technical functions:

- Protect from normal wear and tear

- Protect against excessive friction

- Prevent corrosion and oxidation

- Dissipate heat to transfer power

- Offer compatibility with sealing materials, such as rubber

- Provide a sealing effect as needed

The food and drug industry has a wide range of applications, with specific demands for food-grade lubricants that include but are not limited to:

- Resistance to degradation when exposed to food products, water, steam, or chemicals

- Ability to dissolve sugars

- Possesses a neutral disposition toward elastomers and plastics

All food-grade grease, lubricants, and food-grade silicone must comply with state and federal health and safety regulations. The physical properties must also be:

- Physiologically inert

- Tasteless

- Odorless

- Internationally approved

Why are Food Grade Lubricants Important?

While lubricants should never come in contact with manufactured goods, when contamination of food products occurs, the results can prove disastrous. Recalls rarely happen due to lubricant contamination, but when they do, it can be very costly for the manufacturer.

In the food industry, processors of food and beverage items demand food-grade lubricants to efficiently meet their production demands and eliminate the risk of compromising the safety of the products.

Many lubricants are subject to extreme contaminants from the surrounding environment. For example, a milling factory can produce a significant amount of dust, creating a problem for the filtration systems. A meat processing plant, which requires regular steam cleaning, poses a high contamination risk due to the stringent daily washing procedures. As much as 15% of water by volume can come in contact with gear oils, resulting in a need for a durable lubricant capable of withstanding these types of harsh environments.

The growth of yeast, fungi, bacteria, and other microorganisms also poses a significant risk of contamination to food-grade lubricants and oils. While the risk for contamination in industrial settings can be high, the contaminant risk level in the food production industry is even higher.

Food Grade Categories

The United States Department of Agriculture (USDA) designated the original food-grade categories of H1, H2, and H3. In the United States and worldwide, the National Sanitation Foundation (NSF) monitors a plan that mirrors the USDA program to properly evaluate the use of lubricants on machinery that comes in contact with food products.

In the U.S., facilities wishing to adhere to current U.S. laws must check all labels to ensure the lubricants they use comply with current standards and NSF classification. The system assures consumers that food and drug manufacturers are using food-grade lubricants safe for human consumption.

H1 Lubricants

H1 lubricants are generally used in food-processing settings where there is a risk of incidental contact with food products. Even though the industry refers to them as food-grade lubricants, they are not intended to come in direct, intentional contact with food products.

The amount of lubricant found in food must never exceed 0.001% (10 parts per million). As specified by FDA regulations found in 21 CFR 178.3750, H1 lubricant formulas can only contain the following ingredients:

- Base stock

- Additives

- Thickeners

While H1 lubricants offer beneficial anti-rust properties, they must never contain heavy metals such as lead, arsenic, mercury, mutagens, teratogens, or carcinogens.

Labels for H1 classification must adhere to the following guidelines:

- Clearly state the product intention without being misleading

- Contain the proper usage instructions

- Be traceable to the manufacturer

- Bear the NSF Registration Mark and H1 category code

- Have a unique product registration number

Labels for H1 lubricants typically contain statements such as the following:

- “Food Grade”

- “Ingredients meet FDA Regulation 178.3570”

- “Ingredients meet FDA Regulation 12 CFR 178.3570”

- “Registered with NSF as an H1” or “NSF H1 Registered”

- “Meets USDA 1998 Guidelines”

- “Suitable for Use in the Food Industry”

H2 Lubricants

H2 lubricants are suitable for machine parts and equipment where the possibility of coming into contact with food products is non-existent. For example, an oil used to maintain a forklift can be an H2 lubricant.

Apart from serving as an anti-rust agent, H2 lubricants are also employed as a release agent on machine parts or equipment. H2 lubricants cannot contain the following:

- Antimony

- Arsenic

- Cadmium

- Carcinogens

- Lead

- Mercury

- Mineral Acids

- Mutagens

- Selenium

- Teratogens

- Other intentionally heavy metals

While food processing plants can safely use H2 lubricants, they should never use them on the production line.

H3 Lubricants

H3 lubricants are food-grade lubricants that are used in food processing environments where there is incidental food contact with the lubricated surface. H3 lubricants can be used in a variety of food processing equipment, including mixers, conveyors and slicers, among others.

Applications for Food Grade Greases

Food grade grease proves beneficial in industrial and food processing equipment applications, which can include but are not limited to:

- Plain and rolling element bearings, linkages, joints and slides

- Centralized lubrication systems

- Enclosed gearboxes

To be classified as a food-grade grease, the lubricant must be capable of performing the same technical functions expected of other lubricants and meet the following requirements:

-

- Resists degradation from food products, water, steam and chemicals

- Possesses a neutral behavior when coming in contact with plastics and elastomers

- Be odorless, non-toxic, tasteless, harmless and physiologically inert

Food-grade greases are vital to machinery that processes beverages, candy, beer, soda, tortillas and more.

What are Food Grade Lubricants Made Of?

H1 lubricants commonly consist of synthetic or petroleum-based materials and are typically manufactured using highly refined non-staining mineral oils that are tasteless, colorless and odorless.

Sometimes, food-grade silicones can aid in the manufacturing of H1 lubricants, but they must contain 200 cSt or more viscosity for safe use. This type of H1 lubricant made from silicone possesses the highest oxidation and thermal stability.

H2 lubricant guidelines allow for a larger variety of base stocks since the standards are less restrictive than other lubricants. Many products commonly used in industrial plants that do not process food also get used in various H2 applications for food plants. H3 lubricants must be composed of mineral oils or edible substances such as cottonseed, soybean or corn oils.

Food Safety Modernization Act (FSMA)

Signed into federal law on Jan. 4, 2011, by President Barack Obama, the Food Safety Modernization Act (FSMA) provided the FDA with new authorities to aggressively regulate how foods are grown, processed and harvested.

The FSMA lets the FDA issue mandatory recalls and provides the agency with several new authorities, recognized as the first significant change since 1938 to food safety regulations. The guidelines are similar to the Food Safety Enhancement Act that passed the House legislation in 2009.

The new rules implemented by the FSMA require proper storage of food-grade lubricants, mandating they remain separate from other non-food MRO chemicals. Employees involved in food production must receive advanced training.

Successful Reliability Program Includes Food Grade Grease and Oil

LE is committed to creating effective food processing lubricants and reliability programs so you can enjoy a long equipment lifespan. Our knowledgeable consultants conduct onsite inspections and provide product-specific data – as well as tailored support, recommendations and service – to ensure the success of your reliability program.

LE offers maintenance training, contamination control solutions, fluid handling solutions, and everything else needed to maximize the profitability of food processing operations through optimum maintenance practices. To learn more about our food grade oils, food grade greases, food grade silicone, and other lubricant reliability solutions, please contact LE today.

Look for products that contain Quinplex

Many of LE’s food grade greases and oils contains Quinplex, which is LE’s exclusive additive used to provide outstand water resistance, tackiness and enhanced mechanical stability, and helps to form a barrier against corrosion. Learn more about Quinplex.

Food Grade Grease

H1 Quinplex® Food Machinery Lubricant (4022-4025)

H1 Quinplex Food Machinery Lubricant is aluminum complex thickened grease suitable for a broad operating temperature range. In addition to being a food grade grease – NSF H1 registered for incidental food contact – it is also robust enough to withstand moisture, high temperatures, extreme pressures and other harsh conditions found at food manufacturing plants. It features an aluminum complex thickener base, providing extreme water resistance, excellent mechanical stability, reversibility and tackiness. Key additives include Quinplex, LE’s proprietary impact-resistant additive, and a rust and oxidation inhibitor. Switching to H1 Quinplex Food Machinery Lubricant results in longer bearing life, fewer equipment repairs, less downtime and lower lubricant consumption. Also available in an aerosol.

Typical Applications: Blenders, bottle washers, cams, carbonators, conveyors, cookers, crowners, de-hairing machines, dividers, electric motors, extractors, feather pickers, filling machines, food carts, knives, labelers, mixers, molders, o-rings, packaging machines, proofers, saws, sifters, slicers, slides, and wrappers

Available NLGI Grades: 2 (4025), 1 (4024), 0 (4023), 00 (4022)

H1 Quinplex® High Temperature Lubricant (4051)

This long-lasting food grade grease is nonmelting and provides constant protection for high-temp bearing applications. Bearings operating in or near heat-generating equipment are subject to temperatures that cause ordinary greases to melt and run, leaving critical bearing surfaces unprotected. H1 Quinplex® High Temperature Lubricant is a clay-thickened grease designed to withstand high temperatures, staying in place to provide constant lubrication. It also resists oxidation and vaporization, and repels water. NSF H1 certified, it is a suitable lubricant for use in food processing and other sensitive environments. By ensuring longer lubrication intervals and fewer bearing failures, H1 Quinplex High Temperature Lubricant helps contribute to increased production and a healthier bottom line.

Typical Applications: High-temperature applications where an NSF H1 registered food grade product should be used, including pellet mills, kilns, exhaust fans, oven conveyors, and plastic blow molding machines.

Available NLGI Grades: 1 1/2 (4051)

H1 Quincal™ Syn FG Grease (4070-4072)

Formulated for use in food processing applications, H1 Quincal Syn FG Grease features a synthetic base fluid, calcium sulfonate complex thickener, and Quinplex, LE’s proprietary impact-resistant additive. This premium combination imparts a very high dropping point, exceptional inherent extreme pressure (EP) characteristics, superior mechanical stability, low oil bleed, tackiness and water resistance – everything you need to protect and extend the life of your equipment. NSF H1 registered for incidental food contact, this grease is the right solution for a wide variety of food processing applications. It is especially effective when used on bearings operating in a warm, moist environment or in operations where a lot of water is needed to keep equipment cool. H1 Quincal is robust enough to handle elevated temperatures and other harsh conditions found at food manufacturing plants, resulting in longer bearing life, fewer equipment repairs, less downtime and lower lubricant consumption.

Typical Applications: Works well in variety of food processing applications, including: blenders, cookers, filling machines, canning machines, bottling machines, and packaging equipment

Available NLGI Grades: 2 (4072), 1 (4071), 0 (4070)

Food Grade Penetrating Oil & Lubricant

H1 Quinplex® Penetrating Oil & Lubricant (4058) & Aerosol (4059)

This outstanding H1 food grade penetrating oil and general lubricant works quickly to dissolve rust, gums and varnish to free up frozen parts. H1 Quinplex Penetrating Oil & Lubricant is NSF H1 registered for incidental food contact. It resists rust and corrosion, leaving a light lubricant film for further lubrication and corrosion prevention on metal surfaces. It contains H1 polar organic solvent to assist in water displacement and contains Quinplex, LE’s proprietary additive to improve oil film strength. H1 Quinplex Penetrating Oil & Lubricant is available in bulk sizes and aerosol cans.

Typical Applications: Any area where a penetrating and lubricating oil suitable for incidental food contact is required, including bottling and canning equipment, food processing machinery, slides, cams, chains and other machine surfaces

Available container sizes for 4058: Pail, Drum, 275 gallon tote

Available container sizes for 4059: Single Can and case of 12

Food Grade Silicone Spray

H1 Silicone Spray (804)

H1 Silicone Spray is a great H1 food grade silicone-based aerosol spray for use on machine parts and equipment in locations in which there is potential exposure of the lubricated part to food. Available in an aerosol can.

Typical Applications: Food processing equipment, food packaging equipment, lock mechanisms, rubber door and window seals, ironing and pressing equipment, cutting tables for smooth and even cutting, vending equipment, molding equipment, and dry cleaning equipment

Available container sizes for 804: Single Can and case of 12

Food Grade Gear Oils

H1 Quinplex® Syn FG Gear Oil (4150-4460)

H1 Quinplex Syn FG Gear Oil is an NSF H1 registered synthetic food grade gear oil that protects gears in extreme high and low temperatures in a variety of gearboxes and other critical applications in food and beverage manufacturing facilities. It was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex Syn FG Gear Oil contains 100 percent synthetic base stock. Its anti-wear capability differentiates it from many other white oils on the market. It also offers great seal compatibility and excellent nonfoaming qualities. To ensure good metal adhesion, it contains a shear stable polymeric tackifier system including Quinplex, LE’s proprietary impact-resistant additive.

Typical Applications: Equipment where incidental food contact may occur, including: bearings, gearboxes, open gears, slides, guides, chains, conveyor chains, and valves

Available ISO Viscosity Grades: 150 (4150), 220 (4220), 320 (4320), 460 (4460)

H1 Quinplex® White Gear Lubricant (4090-4250)

H1 Quinplex White Gear Lubricant is an NSF H1 registered food grade oil that protects gearboxes in food production applications. It is also recommended for a variety of other critical applications in food and beverage manufacturing facilities. Formulated to withstand severe loading conditions, prevent rust and corrosion, and provide superior protection at a wide range of operating temperatures, H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks. It offers anti-wear protection, differentiating it from many other white oils on the market. To ensure good metal adhesion, it contains a shear stable polymeric tackifier system including Quinplex, LE’s proprietary impact-resistant additive.

Typical Applications: Equipment where incidental food contact may occur, including: slides, guides, chains, conveyor chains, valves, bearings, gearboxes, open gears, and worm gear applications

Available ISO Viscosity Grades: 220 (4090), 460 (4140), 680 (4250)

Food Grade Oven Chain Lubricant

Ovenworx® H1 Syn Chain Lubricant (4061)

Ovenworx® H1 Syn Chain Lubricant was formulated specifically to combat the demanding conditions present with oven chain applications by offering superior heat resistance. In addition, it is approved for incidental food contact and contains no artificial dyes, making it a good choice for food manufacturing plants needing superior heat resistance. Oven chain efficiency is dependent upon a lubricant that can keep the chain operating freely and smoothly, fighting the ever present heat and moisture that can cause corrosion and eventually lead to premature failure of oven chain pins and bushings. Only the most robust lubricant formulations can perform in this application; it is not an area to cut corners. If the oven chain fails, output comes to a screeching halt.

In addition to this high level of protection, equipment runs more cleanly and efficiently with Ovenworx® H1 Syn Chain Lubricant, which lubricates without the need of solids. Lubricants with solids have to be stirred to keep the solids distributed within the carrier and prevent them from falling out of the suspension. Solids also can create housekeeping issues by building up over time, creating gum and gunk around the application area, especially when over-applied.

Typical Applications: Automatic lubrication systems for baking ovens, kiln chain drives, skate chains in bread and bun baking ovens, stenter & tenter chains, and other high-temperature oven chains

Available ISO Viscosity Grade: 220 (4061)

Food Grade Oils

H1 Quinplex® Synthetic Food Grade Oil (4032-4068)

H1 Quinplex Synthetic Food Grade Oil is an NSF H1 registered synthetic food grade oil formulated for use in food processing and other sensitive environments where superior anti-wear, rust and oxidation resistant properties are required. It clings to equipment and provides reliable water-resistant protection from oxidation, rust and wear. Featuring 100 percent synthetic base oil, H1 Quinplex Synthetic Food Grade Oil has excellent load-carrying abilities, can be used in low-temperature applications, and contain Quinplex, LE’s proprietary impact-resistant additive.

Typical Applications: Bearings, bushings, slides, chains, compressors (including rotary screw air), vacuum pumps and hydraulics used in: animal feed preparation, aluminum/metallic foil and package manufacturing, food processing, paper-making machinery, and textile machinery

Available ISO Viscosity Grades: 32 (4032), 46 (4046), 68 (4068)

H1 Quinplex® White Oil (4010-4040)

LE’s H1 Quinplex® White Oil is an NSF H1 registered lubricant designed to use in food processing equipment where incidental contact may occur or where a clean, nonstaining lubricant is required. It contains Quinplex, LE’s proprietary impact-resistant additive, and is superior to competitive products in oxidation and wear resistance. It reliably extends asset life and decreases the likelihood of expensive unplanned downtime – crucial with high-capital, continuous process equipment.

Typical Applications: Bearings, bushings, slides, guides, chains, compressors, valves, vacuum pumps, and hydraulic systems used in food processing equipment and other applications requiring a food grade or nonstaining lubricant.

Available ISO Viscosity Grades: 46 (4010), 68 (4020), 100 (4030), 150 (4040)

H1 White Utility Oil (4201 4204)

White Utility Oil (4201 & 4204) is a food grade white mineral oil containing a minimal amount of oxidation inhibitor to ensure color stability. It meets the requirements of NSF H1 registered lubricants and is certified Halal by IFANCA and Kosher Pareve. It is suggested for rust prevention after washdown and for other general lubrication applications where incidental food contact can occur or where nonstaining oil is required, such as in textile applications.

Typical Applications: General lubrication applications where incidental food contact can occur. Can also be used for pharmaceutical applications, and for textile applications where non-staining oil is required, including use as spindle oil and needle oil.

Available ISO Viscosity Grades: NA (4201), 46 (4204)

To learn more about our food grade oil and grease solutions, please contact LE.