Is your lubricant storage area working for you?

Almost every industrial operation has a lube room or some central area where lubricants are stored. Contamination issues often start there and are already a problem by the time the lubricants are introduced into the equipment. Knowing this, Lubrication Engineers helps many of its customers transform these areas into world class lubrication storage rooms that incorporate the latest in lubrication best practices. A lubricant storage and dispensing upgrade is a great continuous improvement project and has the potential for a tremendous positive impact on your organization.

Improving your lubricant storage room encompasses several activities and benefits, including:

- Consolidating lubricant inventory and reducing amount of space needed for storage

- Identifying and color-coding lubricants to enhance visual recognition and efficiency

- Reducing mistakes by operators

- Reducing or eliminating contamination before it creates problems

- Improving safety and decreasing waste by eliminating spills

Building new lube room requires a partner

Lubrication Engineers is an authorized distributor for products made by Fluid Defense Systems, Des-Case Corporation and Fluidall – all recognized leaders in lubricant storage product solutions. With all of these options, LE can be your one-stop shop by helping you plan, design and implement your lubricant storage upgrade – choosing the products that are right for your facility. Our trained and certified lubrication consultant can be onsite to assist you every step of the way. We take great pride in making sure your lubricant storage facility fits your needs and meets your goals. Over the years, we have helped our customers with hundreds of new or upgraded best practice lube storage rooms. Let our experience go to work for you.

Single Station & Bulk Handling Lubricant Storage & Dispensing Systems

Oil Safe® 55 Gallon Drum Work Station

Delivering best practice contamination control for 55-gallon drums in a modular, ergonomic and space-efficient manner.

- Delivered pre-assembled and ready-to-use

- Stainless steel dispensing console with drip pan

- Electronic stop / start buttons

- Positive displacement gear pump (3-5GPM) with internal bypass

- 2-way filtration (discharge & re-circulate “kidney-loop”)

- Drum can be placed on any standard drum deck / spill pallet for SPCC spill compliance if required.

Oil Safe® Tote Dispensing Rack

The tote dispensing rack delivers best practice contamination control for common 300-gallon totes in a modular, ergonomic and space-efficient form.

- Delivered pre-assembled and ready-to-use

- Electronic stop / start buttons

- Retractable hose-dispensing reel (25 feet) with trigger dispenser

- Positive displacement gear pump (3-5GPM) with internal bypass

- Rack will accommodate totes with a base dimension less than 41″ w x 46″ d

Poly Tank Lubricant Storage & Dispensing Solutions

Fluidall provides patented poly tank solutions that make storing and dispensing bulk oils, lubricants and fluids reliable, clean, safe and efficient. Fluidall’s Tote-A-Lube® and Wall-Stacker™ series tanks contribute to a better, safer working environment for you and your employees. Both the Tote-A-Lube® and the Wall-Stacker™ stackable storage tanks are low-cost investments that pay high dividends in safety, time, contamination control and efficient use of space.

Tote-A-Lube® Storage Tanks

- Modular design offers space-saving storage for multiple oils, lubricants and fluids

- Available in 35-, 70-, 120-, 180-, 240- and 330-gallon tank sizes

- Industrial-strength, lightweight, stackable and easy to install

- Can be securely stacked together in various configurations

- Each poly tank comes standard with a 1-inch bottom bulkhead, 1- to 2-inch FPT opening on top, and one 2-inch FPT fill-port opening, making them easy to fill while stacked. (Tanks can be customized with additional openings in either the top or sides.)

- Made from rugged, high-quality, food-grade polyethylene that will not rust

- Translucent tanks for easy visual inventory of fluid levels

- Can be used with pump or gravity feed

Configurations:

Wall-Stacker™ Storage Tanks

- Deliver same advantages as Tote-A-Lube® tanks, but with smaller footprint to allow bulk storage for narrow spaces

- Available in 32-, 71- and 115-gallon tank sizes

- Industrial-strength, lightweight, stackable and easy to install

- Can be securely stacked together in various configurations of the three sizes

- Feature patented cutout areas in the bottom of the tanks, making them easy to fill while stacked

- Made from rugged, high-quality, food-grade polyethylene that will not rust

- Translucent tanks for easy visual inventory of fluid levels

- Can be used with pump or gravity feed

Configurations:

Metal Tank Solutions

Oil Safe® Steel Tank Bulk Storage & Dispensing Solutions

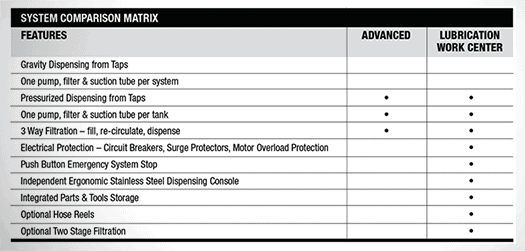

Fluid Defense Systems continues to bring a fresh approach and innovation to lube room transformation projects. Fluid Defense has two Oil Safe® Steel Tank Storage System configurations to suit your needs: Advanced Bulk Storage System and Lubrication Work Center. With any of these two systems, you can take immediate control over your lubrication workflow process, cut down on mistakes, and make your lubricant storage areas clean and efficient.

- Ship fully assembled and ready to go, with very little setup required

- Scalable and configurable system to accommodate the number of lubricants required

- Choice of four aluminized steel tanks in 30-, 65-, 120- and 240-gallon sizes

- Choice of 10 different tank colors with matching identification labeling to ensure a clean, safe and compliant lubricant storage area

- Available in Advanced and Lubrication Work Center configurations