LE Can Help With Any Lubrication Challenge

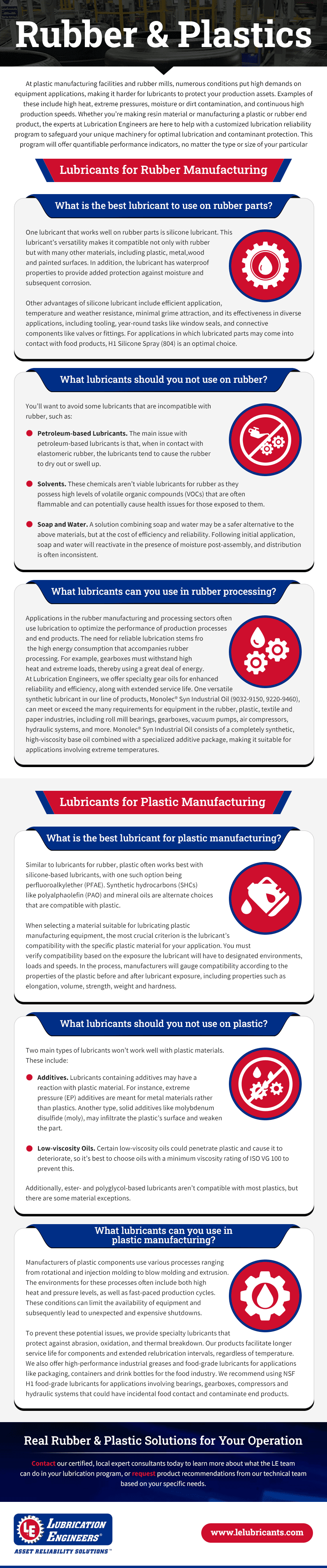

At plastic manufacturing facilities and rubber mills, numerous conditions put high demands on equipment applications, making it harder for lubricants to protect your production assets. Examples of these include high heat, extreme pressures, moisture or dirt contamination, and continuous high production speeds. Whether you’re making resin material or manufacturing a plastic or rubber end product, the experts at Lubrication Engineers are here to help with a customized lubrication reliability program to safeguard your unique machinery for optimal lubrication and contaminant protection. This program will offer quantifiable performance indicators, no matter the type or size of your particular rubber or plastic operation.

Lubricants for Rubber Manufacturing

What is the best lubricant to use on rubber parts?

One lubricant that works well on rubber parts is silicone lubricant. This lubricant’s versatility makes it compatible not only with rubber but with many other materials, including plastic, metal,wood and painted surfaces. In addition, the lubricant has waterproof properties to provide added protection against moisture and subsequent corrosion.

Other advantages of silicone lubricant include efficient application, temperature and weather resistance, minimal grime attraction, and its effectiveness in diverse applications, including tooling, year-round tasks like window seals, and connective components like valves or fittings.

For applications in which lubricated parts may come into contact with food products, H1 Silicone Spray (804) is an optimal choice.

What lubricants should you not use on rubber?

You’ll want to avoid some lubricants that are incompatible with rubber, such as:

- Petroleum-based lubricants. The main issue with petroleum-based lubricants is that, when in contact with elastomeric rubber, the lubricants tend to cause the rubber to dry out or swell up.

- Solvents. These chemicals aren’t viable lubricants for rubber as they possess high levels of volatile organic compounds (VOCs) that are often flammable and can potentially cause health issues for those exposed to them.

- Soap and water. A solution combining soap and water may be a safer alternative to the above materials, but at the cost of efficiency and reliability. Following initial application, soap and water will reactivate in the presence of moisture post-assembly, and distribution is often inconsistent.

What lubricants can you use in rubber processing?

Applications in the rubber manufacturing and processing sectors often use lubrication to optimize the performance of production processes and end products. The need for reliable lubrication stems from the high energy consumption that accompanies rubber processing. For example, gearboxes must withstand high heat and extreme loads, thereby using a great deal of energy.

At Lubrication Engineers, we offer specialty gear oils for enhanced reliability and efficiency, along with extended service life. One versatile synthetic lubricant in our line of products, Monolec® Syn Industrial Oil (9032-9150, 9220-9680), can meet or exceed the many requirements for equipment in the rubber, plastic, textile and paper industries, including roll mill bearings, gearboxes, vacuum pumps, air compressors, hydraulic systems, and more. Monolec® Syn Industrial Oil consists of a completely synthetic, high-viscosity base oil combined with a specialized additive package, making it suitable for applications involving extreme temperatures.

Lubricants for Plastic Manufacturing

What is the best lubricant for plastic manufacturing?

Similar to lubricants for rubber, plastic often works best with silicone-based lubricants, with one such option being perfluoroalkylether (PFAE). Synthetic hydrocarbons (SHCs) like polyalphaolefin (PAO) and mineral oils are alternate choices that are compatible with plastic.

When selecting a material suitable for lubricating plastic manufacturing equipment, the most crucial criterion is the lubricant’s compatibility with the specific plastic material for your application. You must verify compatibility based on the exposure the lubricant will have to designated environments, loads and speeds. In the process, manufacturers will gauge compatibility according to the properties of the plastic before and after lubricant exposure, including properties such as elongation, volume, strength, weight and hardness.

What lubricants should you not use on plastic?

Two main types of lubricants won’t work well with plastic materials. These include:

- Additives. Lubricants containing additives may have a reaction with plastic material. For instance, extreme pressure (EP) additives are meant for metal materials rather than plastics. Another type, solid additives like molybdenum disulfide (moly), may infiltrate the plastic’s surface and weaken the part.

- Low-viscosity oils. Certain low-viscosity oils could penetrate plastic and cause it to deteriorate, so it’s best to choose oils with a minimum viscosity rating of ISO VG 100 to prevent this.

Additionally, ester- and polyglycol-based lubricants aren’t compatible with most plastics, but there are some material exceptions.

What lubricants can you use in plastic manufacturing?

Manufacturers of plastic components use various processes ranging from rotational and injection molding to blow molding and extrusion. The environments for these processes often include both high heat and pressure levels, as well as fast-paced production cycles. These conditions can limit the availability of equipment and subsequently lead to unexpected and expensive shutdowns.

To prevent these potential issues, we provide specialty lubricants that protect against abrasion, oxidation, and thermal breakdown. Our products facilitate longer service life for components and extended relubrication intervals, regardless of temperature.

We also offer high-performance industrial greases and food-grade lubricants for applications like packaging, containers and drink bottles for the food industry. We recommend using NSF H1 food-grade lubricants for applications involving bearings, gearboxes, compressors and hydraulic systems that could have incidental food contact and contaminate end products.

Real Rubber & Plastic Solutions for Your Operation

Whether you’re extruding, compression molding, transfer molding, injection molding, or blow molding, the LE team will point you to the right lubrication solution for maintaining efficient operations in your equipment. We use proprietary formulations in our lubricants to avoid pump wear, offering both viscosity consistency and thermal stability.

Our heavy-duty hydraulic oils also provide supreme resistance to oxidation. Our lubricants will protect your operation’s extruders and tubing machinery against failure. LE;s high-performance greases are effective in electric motors and hydraulic pump bearing protection, and EP gear oils safeguard calendar gearboxes. Also, our desiccant breathers prevent moisture from entering reservoirs.

Interested in cost savings on electrical consumption? Plastic and rubber manufacturers know that an operation’s electric bills far exceed those of lubricant materials and equipment maintenance. Choosing the proper lubricant for your application has energy and budget benefits. The more contact your parts have, the greater their friction, meaning your equipment will require more energy consumption to create movement in part surfaces relative to each other. Additional friction, then, leads to higher costs for electricity. Our lubricant solutions lessen friction, requiring less electricity to drive a compressor, pump, or gearbox.

Contact our certified, local expert consultants today to learn more about what the LE team can do in your lubrication program, or request product recommendations from our technical team based on your specific needs.