LE’s industrial greases: General purpose bearing grease to extreme pressure grease

Lubrication Engineers offers a full line of high-performance industrial greases. Included in the LE grease line are technologically advanced, highly versatile, general purpose, multifunctional, and extreme pressure (EP) varieties, all of which outperform conventional greases. LE’s industrial greases are formulated with a variety of thickener types, including lithium complex, calcium sulfonate, clay (bentone), and polyurea; and they come in a range of NLGI grades.

Our greases go through a rigorous quality process to ensure consistency and performance from batch to batch with greases manufactured in Wichita, Kan. Features of LE greases, which vary depending on the type of grease, include exceptional load-carrying ability, high dropping point, low evaporation rate, low oil separation and mechanical stability. Features such as these make LE greases effective for a wide variety of industrial and fleet applications, including high-temperature and high-moisture operations and extended service under extreme conditions.

LE also supplies food grade greases that meet NSF H1 requirements for incidental food contact and are certified Kosher Pareve by the Orthodox Union and Halal by INFANCA.

LE’s greases are formulated for a variety of industries and applications to provide protection for components and parts such as bearings (roller bearings, linear bearings and other), bucket pins, bushings, cables, cams, chains, chassis, open gears, and slides & ways (slideways). LE greases offer varying benefits such as reduced wear, reduced operating temperatures, longer equipment life, enhanced performance, increased efficiency, increased uptime, lower grease consumption, longer service intervals and reduced maintenance.

Whether you are looking for an extreme pressure grease, lithium complex grease, bearing grease, chassis grease or any other type of high-performance industrial grease, LE has the products and the expertise that you need. You can get LE grease by contacting your local LE consultant or registering to purchase through this website.

Lithium Complex Grease

Almagard® Vari-Purpose Lubricant (3750-3752)

One of our best-selling greases, Almagard Vari-Purpose Lubricant is a lithium complex grease that provides cool-running, long-lasting, water-resistant performance. It dramatically lengthens grease intervals, eliminates bearing failures, can extend bearing life by up to threefold, and does not harden with age. It is recommended for extended service applications and has a high dropping point, Almagard is extremely tacky and will not wash off, pound out or melt and run, even in severe conditions. It is ideal for on-and off-road equipment where high impact occurs, as well as many in-plant applications.

Typical Applications: Chassis, wheel bearings, front axle arrangements, U-joints, bucket pins, bearings

Available Grades: NLGI 2 (3752), NLGI 1 (3751), NLGI 0 (3750)

Monolec® Multiplex Lubricant (4622)

Monolec Multiplex Lubricant is a highly versatile, long-life, lithium complex thickened grease designed for extreme pressure (EP) performance in a variety of farm, fleet, industrial and marine applications. It provides dependable performance in a broad operating temperature range in chassis, wheel bearings and other critical grease points. It meets the requirements of NLGI’s GC-LB grease specification.

Typical Applications: Chassis points, front-axle arrangements, U-joints and wheel bearings in equipment, such as debarkers, ditching machines, dump trucks, forklifts, front-end loaders, and vehicle fleets; plain and anti-friction bearings in a variety of machinery, including conveyors, electric motors and fans; pillowblock bearings

Available Grade: NLGI 2 (4622)

Lithium Hydroxy 12 Grease

Almatek® General Purpose Lubricant (1232)

Almatek General Purpose Lubricant is a lithium hydroxy 12 grease that offers long-lasting protection, versatility and performance. It increases uptime, reduces maintenance costs and lowers lubrication costs. It is a distinctive red color, which shows when fresh lubricant forces out old material. Almatek is recommended for use in construction, marine, mining, industrial and various other heavy-duty equipment applications.

Typical Applications: Various bearing types (friction, anti-friction, conveyor, ball, roller, plain, fan)

Available Grade: NLGI 2 (1232)

Aluminum Complex Grease

Almaplex® Industrial Lubricant (1274-1275)

Almaplex Industrial Lubricant is a versatile wear-reducing aluminum complex grease that protects equipment from moisture & heat. It is a general purpose extreme pressure (EP) grease for heavy industrial use and is extremely versatile, minimizing inventory requirements and misapplication because it works in many different applications. It is especially effective in severe operations caused by moisture or high temperatures. Its robust aluminum complex formulation seals out water and other contaminants that can wreak havoc on the long-term life of equipment. Almaplex grease protects against oxidation, rust and corrosion.

Typical Applications: Plain, anti-friction, high-speed and slow-speed bearings; conveyor, fan and wheel bearings; electric motors; forging equipment; machine tools; presses; rotary aerators; U-joints. Almaplex 1274 works well in centralized lubrication systems.

Available Grades: NLGI 2 (1275), NLGI 1-1/2 (1274)

Almaplex® Ultra-Syn Lubricant (1295-1299)

Almaplex Ultra-Syn Lubricant is a heavy-duty synthetic grease that provides optimum performance under extreme operating conditions. It is an aluminum complex thickened grease made with an ISO 460 viscosity synthetic base fluid, a combination that provides superior high-temperature functionality, low-temperature pumpability and excellent performance in the presence of water. It also contains LE’s proprietary additives Almasol® and Quinplex®.

Almaplex 1299 & 1298 (NLGI grades 2 & 1, respectively) provide 73 percent higher extreme pressure (EP) performance than competitive grease, as indicated by the results of the Four Ball EP Test. In the Water Spray-Off Test, competitive greases lost almost six times more grease. This performance offers the potential for energy savings and reduced operating temperatures in applications such as construction, agriculture, mining, steel mills and paper mills; hammer mills; extruders and ball mills

Typical Applications (Almaplex 1299 & 1298): Ball mill and kiln pinion support bearings; construction, agricultural and mining equipment; couplings (1299 only); extruders; filter presses and dewatering presses; hammer mills; paper mill wet end, press rolls, felt rolls and calendar stack bearings; steel mill hot and heavily loaded bearings

Typical Applications (Almaplex 1295): Automatic lubrication systems, heavily loaded bearings in cold-temperature operations, heavily loaded gearboxes that require a semifluid grease, leaky gearboxes, printing presses, sealed bearings operating at elevated temperatures

Available Grades: NLGI 000 (1295), NLGI 1 (1298), NLGI 2 (1299)

Earthwise™ EAL Wire Rope Grease (3353)

Earthwise EAL Wire Rope Grease (3353) is an NLGI 0 grease recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP).

It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation. Its robust additive package, including LE’s proprietary Almasol® and Quinplex® additives, further helps it protect against wear, corrosion, impact, rust and oxidation.

Typical Applications: Applications on or near waterways, including: wire rope, chains (links, pins, bushings), cables (sheave bushings, bearings & strands), open and closed silent and roller chains. Ideal for use in automatic wire rope lubricators.

Available Grade: NLGI 0 (3353)

H1 Quinplex® Food Machinery Lubricant (4022-4025)

H1 Quinplex Food Machinery Lubricant is a semi-synthetic grease suitable for a broad operating temperature range. In addition to being a food grade grease – NSF H1 registered for incidental food contact and certified Kosher Pareve by the Orthodox Union and Halal by INFANCA – it is also robust enough to withstand moisture, high temperatures, extreme pressures and other harsh conditions found at food manufacturing plants. It features an aluminum complex thickener base, providing extreme water resistance, excellent mechanical stability, reversibility and tackiness. Key additives include Quinplex®, LE’s proprietary impact-resistant additive, and a rust and oxidation inhibitor. Switching to H1 Quinplex Food Machinery Lubricant results in longer bearing life, fewer equipment repairs, less downtime and lower lubricant consumption.

Typical Applications: Blenders, bottle washers, cams, carbonators, conveyors, cookers, crowners, de-hairing machines, dividers, electric motors, extractors, feather pickers, filling machines, food carts, knives, labelers, mixers, molders, O-rings, packaging machines, proofers, saws, sifters, slicers, slides, wrappers

Available Grades: NLGI 2 (4025) – also available as an aerosol spray, NLGI 1 (4024), NLGI 0 (4023), NLGI 00 (4022)

Monolec® Industrial Lubricant (4700-4702)

Monolec Industrial Lubricant is formulated specifically for use in centralized lubrication systems. It ensures consistent pumpability for reliable equipment protection in a variety of industrial applications where pumpable medium-EP grease is required, and is especially useful for low-temperature grease applications. This versatile aluminum complex grease provides excellent water resistance and will not form permanent emulsions when moisture is present, further protecting equipment from the effects of rust and corrosion. It contains Monolec®, LE’s proprietary wear-reducing additive that provides additional protection from wear, friction and heat; and it contains an extreme pressure (EP) additive for performance when heavy loads are present.

Typical Applications: Centralized automatic lubrication systems, Angelus Sanitary Can Machine (4701), diamond power soot blowers (4702)

Available Grades: NLGI 1 (4701), NLGI 0 (4702), NLGI 00 (4700)

Calcium Sulfonate Complex Grease

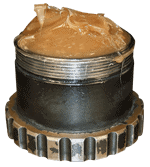

Monocal® GP Grease (1498-1499)

Monocal® GP Grease protects equipment from heat, moisture and heavy loads. It is intended for use in severe conditions such as high temperatures, heavy loads and water. Its high-performance formula features high-viscosity base fluid, calcium sulfonate complex thickener and Monolec®, LE’s proprietary wear-reducing additive. This premium combination imparts a very high dropping point, exceptional inherent extreme pressure (EP) characteristics, superior mechanical stability, low oil bleed, and water resistance – everything you need to protect and extend the life of your equipment. A versatile general purpose lubricant, Monocal GP Grease is the right solution for industrial and mobile equipment used in a wide variety of industries. It is especially effective when used on bearings operating in a warm, moist environment or in operations where a lot of water is needed to keep equipment cool.

Typical Applications: Industrial: bearings (anti-friction, conveyor, fan, heavily loaded ball, high-speed, plain, roller element, slow-speed), forging equipment, machine tools, presses, rolling mills and rotary aerators. Automotive: ball joints, chassis, front axle arrangements, U-joints, wheel bearings

Available Grade: NLGI 2 (1499), NLGI 1 (1498)

Almamoly® HD Grease (1487-1488)

Almamoly HD Grease is a solid lubricant-containing, calcium sulfonate complex-thickened lubricant for use in severe conditions such as high temperatures, heavy loads and water. This high-performance grease is intended for long-lasting use in heavy-duty mobile equipment such as that used in construction, agriculture, open pit mining and road-building. It contains Almasol®, LE’s proprietary solid additive, as well as 5 percent molybdenum disulfide (also known as molydisulfide or moly). Compared to other solid lubricant-containing greases that rely on moly or graphite alone, Almamoly HD Grease’s synergistic combination of moly and Almasol gives it better wear resistance. This unique combination of solids helps ensure reliable lubrication, staying in place even when the lubricant is squeezed out of the contact zone due to extreme pressure (EP) or heavy shock loading. The calcium sulfonate complex thickener provides additional performance features that make this grease desirable for a variety of extreme conditions.

Typical Applications: Large mobile equipment used for agriculture, construction, open pit mining and road-building, including articulated trucks, backhoes, bulldozers, conveyors, crushers, excavators, loaders and shovels. Swiveling and pivoting parts including articulated joints, bucket pins, sleeve bearings, pivot bearings, hinge pins, latches, locks, spindles, threaded parts, cams, and slides. Other applications such as continuous casters, motor-operated steam valves, and underwater applications

Available Grades: NLGI 1 (1488), NLGI 0 (1487)

H1 Quincal™ Syn FG Grease (4070-4072)

Formulated for use in food processing applications, H1 Quincal Syn FG Grease features a synthetic base fluid, calcium sulfonate complex thickener, and Quinplex, LE’s proprietary impact-resistant additive. This premium combination imparts a very high dropping point, exceptional inherent extreme pressure (EP) characteristics, superior mechanical stability, low oil bleed, tackiness and water resistance – everything you need to protect and extend the life of your equipment. NSF H1 registered for incidental food contact and certified Kosher Pareve by the Orthodox Union and Halal by INFANCA, this grease is the right solution for a wide variety of food processing applications. It is especially effective when used on bearings operating in a warm, moist environment or in operations where a lot of water is needed to keep equipment cool. H1 Quincal is robust enough to handle elevated temperatures and other harsh conditions found at food manufacturing plants, resulting in longer bearing life, fewer equipment repairs, less downtime and lower lubricant consumption.

Typical Applications: Works well in variety of food processing applications, including: blenders, cookers, filling machines, canning machines, bottling machines, and packaging equipment

Available Grades: NLGI 2 (4072), NLGI 1 (4071), NLGI 0 (4070)

Polyurea Grease

Monolec® Extend EM Grease (1282)

Formulated with polyurea thickener and designed specifically for use in electric motor bearings, Monolec Extend EM Grease offers superior mechanical stability for long service life. It features low bleed characteristics, excellent pumpability and great oxidation resistance. It is especially effective when severe industrial operating conditions such as extreme temperatures and high speeds are present. It is great for electric motor applications.

Typical Applications: Electric motor bearings; automotive bearings in generators, alternators and starters. (Not for wheel bearings and automotive chassis applications.)

Available Grade: NLGI 2 (1282)

Clay (Bentone) Grease

Almasol® High Temperature Lubricant (1250)

Almasol High Temperature Lubricant is good for bearings operating in or near heat-generating equipment that are subject to temperatures that cause ordinary greases to melt and run, leaving critical bearing surfaces unprotected. It is a clay (bentone) thickened grease and is designed to withstand high temperatures, staying in place to provide constant lubrication. It also resists oxidation and vaporization. By ensuring longer lubrication intervals and fewer bearing failures, Almasol High Temperature Lubricant helps contribute to increased production and a healthier bottom line.

Typical Applications: High-temperature applications, including: asphalt plants, brick/ceramic kilns, exhaust fans, kiln car bearings, lime kilns, oven conveyors, pellet mills, plastics and soot blowers

Available Grades: NLGI 2 1/2 (1250), NLGI 1 (1251)

H1 Quinplex® High Temperature Lubricant (4051)

This long-lasting food grade grease is non-melting and provides constant protection for high-temp bearing applications. Bearings operating in or near heat-generating equipment are subject to temperatures that cause ordinary greases to melt and run, leaving critical bearing surfaces unprotected. H1 Quinplex® High Temperature Lubricant is a clay-thickened grease designed to withstand high temperatures, staying in place to provide constant lubrication. It also resists oxidation and vaporization, and repels water. NSF H1 certified, it is a suitable lubricant for use in food processing and other sensitive environments. By ensuring longer lubrication intervals and fewer bearing failures, H1 Quinplex High Temperature Lubricant helps contribute to increased production and a healthier bottom line.

Typical Applications: High-temperature applications where an NSF H1 registered food grade product should be used, including pellet mills, kilns, exhaust fans, oven conveyors, and plastic blow molding machines.

Available Grades: NLGI 1 1/2 (4051)

Almasol® Syntemp Lubricant (9901)

Designed for high-temperature applications, Almasol Syntemp Lubricant is a heavy-duty extreme pressure (EP) grease made from a very heavy synthetic fluid and non-melting clay (bentone) base. It is specially formulated to provide exceptional protection at temperatures at which petroleum oils would completely oxidize (or carbonize). It is good for use on large open gears exposed to very high temperatures and is also recommended for use on kiln girth gears, large industrial gearing, oven chains, sliding surfaces, large slow moving (friction) bearings and similar applications. It contains Almasol®, LE’s exclusive wear-reducing additive, and has exceptional water resistance. It remains unaffected by boiling water and steam. It also contains special rust inhibitors that prevent rust and corrosion.

Typical Applications: Open gears (kiln girth gears), low speed plain bearings, oven chains, cables, and sliding surfaces operating in a high-temperature environment

Available Grades: NLGI 2 (9901)

Calcium Grease

Wirelife® Almasol® Coating Grease (451-453)

Wirelife Almasol Coating Grease is a soft, semifluid calcium-based grease designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts, seal out damaging moisture, protect against premature wear and shield metal against corrosive attack.

Typical Applications: Wire rope, chain links, pins, bushings, cable sheave bushings, cables, open and closed silent and roller chains, and small, slow-turning gearboxes that require a semifluid lubricant

Available Grades: NLGI 0 (453), NLGI 00 (452), NLGI 000 (451)

Fumed Silica Grease

Pyroshield® Syn Kiln Grease (5190)

Pyroshield Syn Kiln Grease features a high auto-ignition point and contains a synthetic thickener with organic and solid metallic film-forming components as well as Almasol, LE’s exclusive wear-reducing additive. The product’s high content of lubricating solids fills the surface imperfections, resulting in a smoother surface, lower friction and less wear. It can be applied with a variety of applicators, including portable or fixed, manual or automatic, and air- or electric-powered. It is specifically designed for application between the tire bore and filler bars, the sides of the tire and on the stop blocks of kilns but is also suitable for other equipment with wear surfaces that operate at high temperatures.

Typical Applications: Tire bore (inside diameter), wear pads, stop blocks and leaf seals in rotary kilns, horizontal calciners and dryers.

Available Grades: NLGI 0.5

To learn more about our industrial greases, please contact LE today.