Large open gears on grinding and pulverizing mills present significant lubrication challenges.

These challenges are due to the high-load, heavy-shock nature of the application and constant exposure to harsh environmental conditions, such as cement, limestone, coal or silica dust.

Lubrication reliability best practices for open gears include selecting the right lubricant and the right method of application to combat these challenges. Choosing wisely will help protect the gears from wear, increase uptime, and – in most cases – dramatically reduce gear set operating temperatures, lubricant consumption, energy consumption, and waste disposal.

This will lead to a cleaner, safer working environment. The right choice for open gears is a heavy-duty, high viscosity lubricant with an extreme pressure, anti-wear additive package. A lubricant with a Timken rating of 70 pounds or more reduces wear and extends gear life.

In the past, open gear lubricants were asphaltic-based, had Timken ratings of 20 to 25 pounds, and relied on excessive volume for adequate protection. Most open gear lubricants on the market today use a variety of thickeners, such as graphites, silicas and traditional soap thickeners. With these newer types of lubricants, operators still report excessive consumption that leads to difficulty with the lubricants building up around the shrouds, not draining well and creating housekeeping issues.

Other concerns include needing to be heated for pumpability, plugging spray system nozzles, not spraying in low temperatures, drawing in contaminants, obscuring the gear from visual inspection, and not reducing gear temperatures.

LE’s Pyroshield lubricant is a cool, clear, clean, pumpable solution for easily lubricating open gears at far less cost in the end. Kilns, finish mills and other open gear applications are no longer the nasty place you don’t want to be – thanks to Pyroshield and LE’s other open gear solutions.

Identify Suffering Points

Move forward with LE’s proven solutions for extending open gear life.

Wear

Wear

Open gears experience high-load, heavy-shock conditions and a dusty environment that can lead to surface wear like scoring, pitting and spalling. An inferior lubricant will not stand up to extreme conditions. An extremely tacky lubricant with high film strength is needed.

LE Solution:

LE Solution:

Heavy-duty synthetic Pyroshield® Open Gear Lubricants exhibit exceptionally high film strength to provide outstanding protection for high-load, heavy-shock applications. Formulated specifically for open gear applications, they cling tenaciously to metal surfaces without accumulating; prevent metal-to-metal contact; and, in most cases, reduce gear temperatures. Pyroshield lubricants flow from shrouds and are pumpable at temperatures down to 0˚C (32˚F).

Housekeeping, Consumption & Gear Inspection

Housekeeping, Consumption & Gear Inspection

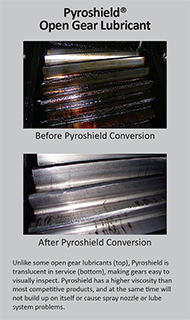

Because many lubricants for open gear systems are not sufficiently tacky or high viscosity, they have to be applied in excessive amounts to provide a thick coating. Some operators use two to three times more lubricant than recommended. This leads to the need for extensive cleanup and waste disposal, and can make it difficult to visually inspect the gear.

LE Solution:

LE Solution:

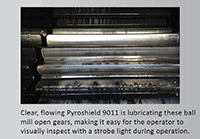

Pyroshield lubricants are extremely tacky and cling to metal without buildup. Pyroshield is translucent once applied, allowing for a visual inspection of the gear surfaces. With high-viscosity Pyroshield, LE customers have been able to reduce the amount used, which means a reduction in lubricant consumption, cleaning and waste disposal.

Automatic Lubrication Systems & Lubricant Conversion

Automatic Lubrication Systems & Lubricant Conversion

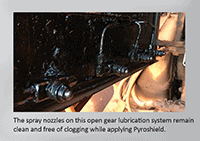

The lubricant needs to be applied evenly and consistently to prevent wear. To ensure this, the spray patterns on automatic lubrication systems must remain consistent, which means it is critical to prevent the nozzles from clogging due to excessive lubricant buildup.

LE Solution:

LE Solution:

LE personnel work with customers to help design the right automatic lubrication system. They also help during the lubricant conversion process to optimize lubrication intervals and establish spray patterns with an emphasis on achieving overlapping patterns. Converting ball mills and kilns is simple using LE’s proven, effective and safe procedure that provides no interruption in production or operation.

Lubrication Engineers can help put together a lubrication reliability program for your open gear applications to help them last longer, eliminating downtime and reducing maintenance costs. Our certified lubrication experts can be onsite to help put together a program that will bring lubrication excellence to your operation. Get started by finding your local LE consultant or registering to purchase online.

Need a product recommendation? Click here to get started/find-consultant/