Your compressor lubricant plays a critical role in protecting internal metal parts, preventing corrosion and wear, and sealing.

Requirements vary considerably based on compressor type, the environment in which it is used, and the type of gas that is being compressed. Therefore, it is imperative that you use a high-quality oil suitable for the application and environment. Also, be sure to match the ISO grade to the OEM spec.

We can help with this by recommending lubrication reliability best practices – including the right oil – for most compressor types. For example, we can help with centrifugal compressors, reciprocating compressors, rotary screw compressors, rotary vane compressors and dry screw compressors. In fact, we have years of documented success helping our customers maximize uptime while reducing costs.

Qualities of High-Performance Oil for Use in Compressors

- Turbine quality premium oil

- High viscosity index

- High-quality oxidation package exceeding 5,000 hours, per ASTM D943

- Rust and corrosion resistant

- Nonfoaming in use

- Demulsibility properties (ability to shed water)

- Filterable without additive depletion

Reliability Solutions

After selecting your compressor oil, the next step is to put the other lubrication reliability pieces in place. First, add oil analysis to begin predictive trending of the oil and asset condition. Second, use filtration to keep the oil clean and dry. With these solutions, you can safely extend the life of the asset and the oil, which will in turn save you time and money.

Identify Suffering Points & Move Forward with Our Proven Solutions

Oxidation

Problem

Problem

Oil life is reduced by half for every 10°C (18°F) in temperature increase. That’s why a strong antioxidant package is essential in a compressor oil. As oil oxidizes, its viscosity increases, varnish forms, sludge and sediments begin to plug filters, acid increases, and rust and corrosion form. (See photo for progression from new to fully oxidized oil.) As a result of oxidation, both oil and equipment have shortened lifespans.

LE Solution

LE Solution

Our high-performance oils are designed to combat the effects of high temperatures, water, contaminants, and heavy loads. These long-lasting oils, listed below, are nonfoaming and offer superior resistance to heat, oxidation and moisture. As a result of their premium formulations, our compressor oils outperform conventional compressor oils. In addition, many exceed OEM requirements.

Unnecessary Oil Changes

Problem

Problem

If you are changing oil based on a time interval, you may be getting rid of perfectly good oil and spending money unnecessarily on excess downtime, maintenance, and lubricant.

LE Solution

LE Solution

Transitioning from time-based to condition-based oil changes will maximize uptime, save money, and make your operation more efficient. As such, a good oil analysis program is integral to any successful lubricant reliability program. With consistent monitoring of the oil’s condition, you can improve your bottom line with less lubricant to purchase, fewer parts to keep in inventory, less used lubricant requiring disposal, less labor, and less downtime. That’s why we recommend our oil analysis program, which monitors for mechanical, operational and environmental factors that can affect equipment and oil life.

Energy Consumption

Problem

Problem

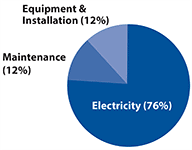

The U.S. Department of Energy states that for an average industrial facility, approximately 10% of electricity consumption is for compressed air generation. In some plants, that number can be as high as 30%. That means compressed air is one of the most expensive sources of energy in a plant, with the efficiency of a typical compressed air system rated as low as 10%.

LE Solution

LE Solution

By reducing friction, you reduce the heat of the equipment and the amount of energy consumed. Even between highly machined metal surfaces, contact occurs. And, the greater the amount of contact, the greater the friction. As a result, more energy is required to move the surfaces. The use of high-performance lubricants can reduce this friction, thus requiring less electricity. And so, it is not uncommon for factories adopting a lubrication reliability program to save 5 to 20% on electricity.

Lubrication Reliability Program

In conclusion, Lubrication Engineers can help put together a lubrication reliability program for your compressors to help them last longer, subsequently eliminating downtime and reducing maintenance costs.

Our certified lubrication experts can be onsite to help put together a program that will bring lubrication excellence to your operation. Start now by finding your local LE consultant or registering to purchase online.