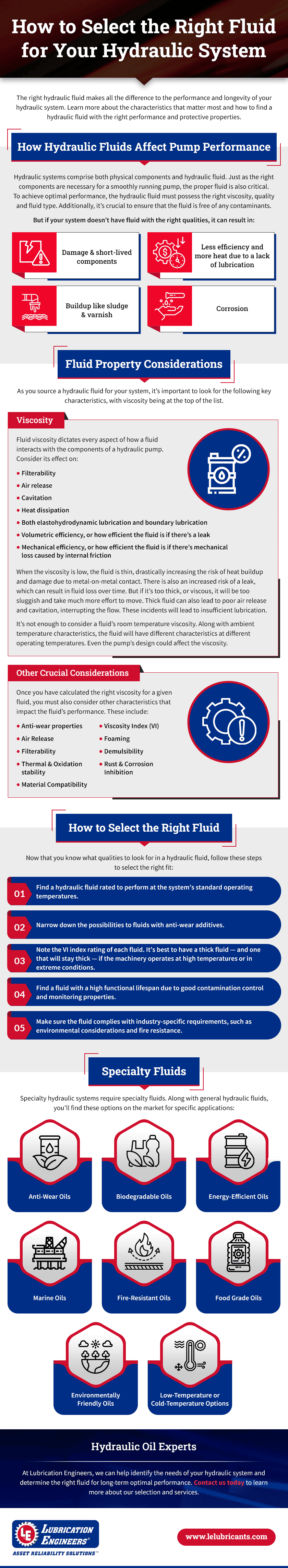

How to Select the Right Fluid for Your Hydraulic System

The right hydraulic fluid makes all the difference to the performance and longevity of your hydraulic system. Learn more about the characteristics that matter most and how to find a hydraulic fluid with the right performance and protective properties.

How Hydraulic Fluids Affect Pump Performance

Hydraulic systems comprise both physical components and hydraulic fluid. Just as the right components are necessary for a smoothly running pump, the proper fluid is also critical. To achieve optimal performance, the hydraulic fluid must possess the right viscosity, quality and fluid type. Additionally, it’s crucial to ensure that the fluid is free of any contaminants.

But if your system doesn’t have fluid with the right qualities, it can result in:

- Damage and short-lived components

- Less efficiency and more heat due to a lack of lubrication

- Buildup like sludge and varnish

- Corrosion

Fluid Property Considerations

As you source a hydraulic fluid for your system, it’s important to look for the following key characteristics, with viscosity being at the top of the list.

Viscosity

Fluid viscosity dictates every aspect of how a fluid interacts with the components of a hydraulic pump. Consider its effect on:

- Filterability

- Air release

- Cavitation

- Heat dissipation

- Both elastohydrodynamic lubrication and boundary lubrication

- Volumetric efficiency, or how efficient the fluid is if there’s a leak

- Mechanical efficiency, or how efficient the fluid is if there’s mechanical loss caused by internal friction

When the viscosity is low, the fluid is thin, drastically increasing the risk of heat buildup and damage due to metal-on-metal contact. There is also an increased risk of a leak, which can result in fluid loss over time. But if it’s too thick, or viscous, it will be too sluggish and take much more effort to move. Thick fluid can also lead to poor air release and cavitation, interrupting the flow. These incidents will lead to insufficient lubrication.

It’s not enough to consider a fluid’s room temperature viscosity. Along with ambient temperature characteristics, the fluid will have different characteristics at different operating temperatures. Even the pump’s design could affect the viscosity.

Other Crucial Considerations

Once you have calculated the right viscosity for a given fluid, you must also consider other characteristics that impact the fluid’s performance. These include:

- Anti-wear properties: Anti-wear additives can alleviate the risk of direct metal-to-metal contact with thin fluids. Zinc-based additives, or zinc dialkyl dithiophosphate (ZDDP), are the most popular type of anti-wear additive. Zinc-free additives, however, are a superior choice for reducing the risk of hydrolysis, corrosion or environmental harm.

- Viscosity Index (VI): High-VI fluids stay viscous at high temperatures, while low-VI fluids do not.

- Thermal and oxidation stability: You may need a fluid that resists oxidation due to water, heat or the presence of wear metals. Oxidizing oil creates acidic byproducts.

- Air release: Having air trapped in the system can lead to cavitation and reduced efficiency.

- Foaming: Fluids can develop the tendency to foam if they’re contaminated by degraded byproducts, water, air or other factors. System design can also increase agitation and, as a result, increase foaming.

- Filterability: An oil that can be passed through a filter to remove contaminants without removing important additives is desirable as the filtration will increase its effective lifespan.

- Demulsibility: This characteristic measures an oil’s ability to release water, which is especially crucial in humid environments.

- Rust and corrosion inhibition: Some fluids have rust inhibitors that thinly coat metal surfaces and reduce the risk of corrosion.

- Material compatibility: Carefully select a hydraulic fluid that won’t degrade any rubber or elastomeric gaskets, seals, hoses or accumulators.

How to Select the Right Fluid

Now that you know what qualities to look for in a hydraulic fluid, follow these steps to select the right fit:

- Find a hydraulic fluid rated to perform at the system’s standard operating temperatures.

- Narrow down the possibilities to fluids with anti-wear additives.

- Note the VI index rating of each fluid. It’s best to have a thick fluid — and one that will stay thick — if the machinery operates at high temperatures or in extreme conditions.

- Find a fluid with a high functional lifespan due to good contamination control and monitoring properties.

- Make sure the fluid complies with industry-specific requirements, such as environmental considerations and fire resistance.

Specialty Fluids

Specialty hydraulic systems require specialty fluids. Along with general hydraulic fluids, you’ll find these options on the market for specific applications:

- Anti-wear oils

- Biodegradable oils

- Energy-efficient oils

- Environmentally friendly oils

- Fire-resistant oils

- Food grade oils

- Low-temperature or cold-temperature options

- Marine oils

Hydraulic Oil Experts

At Lubrication Engineers, we can help identify the needs of your hydraulic system and determine the right fluid for long-term optimal performance. Contact us today to learn more about our selection and services.