Testimonials

Pyroshield® Syn Open Gear Grease significantly reduces maintenance costs and hazards at Rotary Storyland & Playland.

key takeaways

Challenge

Switching to a more effective lubricant could save the Fresno Rotary Club hundreds of dollars annually on cleaning and clothes replacement, reduce maintenance time, and lower operational noise levels.

LE solution

Pyroshield® Syn Open Gear Grease (5182) is a lead-free, extreme pressure lubricant designed for severe service in the mining industry, suitable for open gears, large chains, cables, fifth wheels, and other sliding mechanisms.

Results

Switching to Pyroshield 5182 has eliminated grease issues, saving the Rotary Club hundreds annually on clothing costs and $5,264 in labor for one ride, with further savings expected from reduced lubricant expenses across seven other rides.

I am totally satisfied with the LE products and service. They have cut my maintenance hours more than in half and allowed my crew to focus on improving aesthetics in the park. Our goal is to become 100 percent LE by year’s end.

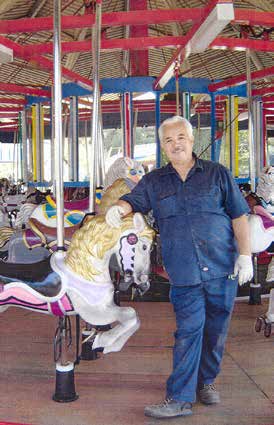

- Alfredo Ramirez, Maintenance Manager

Customer Profile

Rotary Storyland & Playland is an amusement park created by the Fresno Rotary Club, focusing on children ages 3-12. They have been in business more than 50 years and an LE customer since June 2004.

Application

They have eight amusement park rides at Storyland & Playland, with the carousel being one of the most popular.

Challenge

While using a commercial grade lubricant, the grease would sling/melt off the 10-foot gears onto the riders, operators and carousel horses, causing a mess and hazard. This problem cost the Fresno Rotary Club hundreds of dollars yearly for clothes replacement and cleaning. It also required two maintenance workers to regrease the 10-foot gears every other day for 1-2 hours. In addition, the noise level during operation was very high.

LE Solution

The local LE lubrication consultant, recommended Pyroshield® Syn Open Gear Grease (5182), which is a revolutionary lubricant developed for the mining industry and open gears which operate in the most severe service. It is an extreme pressure (EP) lubricant that is lead free, and ideal for open gears, large chains, cables, fifth wheels and various other sliding mechanisms.

Results

Since changing to Pyroshield 5182, the grease sling/melt problem has been eliminated. The result is the elimination of clothing replacement/cleaning, saving the Rotary Club hundreds of dollars per year. Pyroshield 5182 also reduced the maintenance requirements to one worker every other week for half an hour. Alfredo Ramirez, maintenance manager, calculates the savings to be $5,264 per year in labor costs for just this ride alone. There are seven other rides in the park and Alfredo estimates he will save 50 percent on his lubricant costs this year.

Alfredo states, “I am totally satisfied with the LE products and service. They have cut my maintenance hours more than in half and allowed my crew to focus on improving aesthetics in the park. Our goal is to become 100 percent LE by year’s end.”