Testimonials

Windsor-Stevens Paper Company significantly reduced costs and improved equipment efficiency using LE lubricants.

key takeaways

Challenge

Ralph Tropeano, vice president of manufacturing, identified issues with unreliable lubricators and low-viscosity oil causing $5,000 in annual losses, prompting discussions with Lubrication Technologies to enhance mill competitiveness and profitability.

LE solution

Dave recommended installing an Interlube TX automatic lubrication system with LE’s All Purpose Turbine Oil (4946) for rust protection and oxidation stability, while Duolec® Vari-Purpose Gear Lubricant (1605) was used in the Beloit Jones Pulper gearbox for thermal stability and extreme pressure lubrication.

Results

The installation of LE’s 4946 and conversion to Duolec 1605 have resulted in a total savings of $32,301.90, with $30,000 from bearing failure prevention and $2,301.90 from reduced electrical consumption.

Customer Profile

Windsor-Stevens Inc., is an employee owned company located in Windsor, Connecticut. The building they occupy was originally a cotton fabric mill built in 1832. In the mid 1800s it was converted to a paper mill. The paper machine and stock preparation equipment were completely rebuilt and replaced between 1954 and 2000. Today, Windsor-Stevens has a well-equipped fiberboard machine. The mill is unique in that it is the only unit in the United States that manufactures specialty fiberboard using the multi wet ply-back principle. This method limits volume of production but results in an excellent, high quality product. Individual lightweight, highly hydrated layers of fiber are formed, pressed and repressed. The company manufactures high strength electrical insulation and specialty fiberboards that are typically used in electrical, mechanical and automotive applications.

Application

This operation uses a calender stack consisting of a number of rolls, one atop the other, supported by poured babbitted bearings. They also use a Beloit Jones Pulper. The Beloit Jones Pulper is a batch machine used an average of 25 hours weekly. The gearbox of this machine holds 36 gallons of oil. It is a key piece of equipment without which production is not possible.

Challenge

Ralph Tropeano, vice president manufacturing, started working at the mill in 1993. He is ever vigilant in seeking ways and methods to keep the mill competitive and profitable. Dave Piangerelli of Lubrication Technologies met with Mr. Tropeano and discussed the calender stack and its problematic operation. A gravity drip feed type lubricator, that was not reliable, lubricated these bearings.

The occasional failure of the lubricator to operate properly resulted in the failure of bearings, which cost the company an average of $3,000 per year in lost production. The additional cost to repour the bearings was put at approximately $2,000 per year.

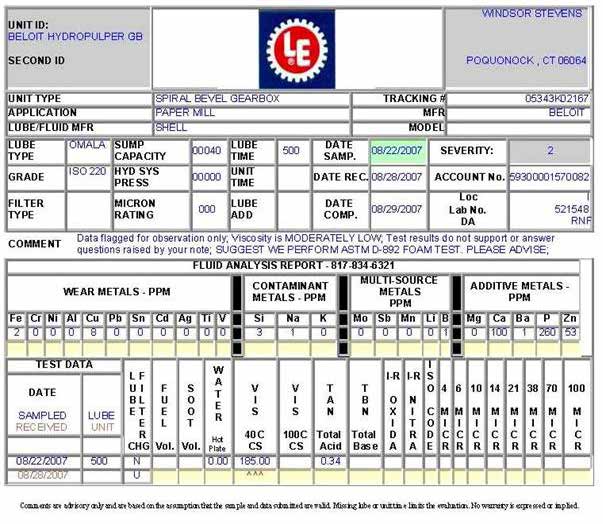

Mr. Tropeano also expressed concern for the Beloit Jones Pulper gearbox. Mr. Tropeano was worried about a foaming issue with the product being used, Shell Omala 220, and higher than usual amperage readings. A sample of the Shell product was obtained and it appeared that the product had exhibited some shearing resulting in a lower viscosity than that recommended by the manufacturer of the pulper. The viscosity of the Omala 220 was 185 cSt @ 40˚C, far below the ISO 220 range.

LE Solution

Dave recommended the installation of an Interlube TX automatic lubrication system for the calender stack and the use of LE’s All Purpose Turbine Oil (4946). LE’s 4946 is a turbine oil designed with additives that offer excellent rust protection and exceptional oxidation stability. Lubrication Technologies provided the system components and Mr. Tropeano’s crew facilitated the installation of the system.

Duolec® Vari-Purpose Gear Lubricant (1605) was installed in the Beloit Jones Pulper gearbox. Duolec 1605 is a high performance industrial and automotive gear oil. It is designed for use in any industrial gear or bearing application that requires a thermally stable, extreme pressure lubricant.

Results

Since the installation of the system and LE’s 4946 for the calendar stack in 2001, there have been no bearing failures in this application resulting in a savings of $5,000 per year, or $30,000 to date.

Since the conversion to Duolec 1605 in the Beloit Jones Pulper, an immediate reduction of amperage was noted. Dropping from an average of 220 amps to between 205 and 210 amps.

The following is used to calculate the estimated yearly savings:

.Volts X Amps Saved X 1.73 (3-phase conversion factor) = kW Saved kW X Hours of Operation = kWh Saved

kWh X Electrical Energy Cost = Dollars saved

In addition, the Duolec 1605 in the pulper will be analyzed periodically and based on past experience with LE gear oil in pulper gearboxes, the life of the oil is estimated to double when compared to the previous oil, resulting in additional savings regarding waste oil generation and handling.

.575v X 10a X 1.73 = 9.9475 kW 9.9475 kW X 1,300 hr = 12,932 kWh 12,932 x $0.178/kWh = 2,301.90

Yearly electrical savings are estimated to be $2,301.90.