Testimonials

Almaplex® Ultra-Syn Lubricant significantly improved operational efficiency and reduced costs for a corrugating customer.

key takeaways

Challenge

High amperage issues and water contamination on glue rolls were problematic, while lubricating the corrugator’s tapered roller bearings cost over $120 per pound of lubricant.

LE solution

Almaplex® Ultra-Syn Lubricant (1299) and Almatek® General Purpose Lubricant (1232) are specialized greases used for corrugator pre-heat rolls, tapered roller bearings, and cold bearings, enhancing performance and reducing wear with synthetic base fluids and exclusive additives.

Results

Switching to Almaplex 1299 reduced lubricant costs by approximately 30%, decreased amperage, minimized stock needs, and eliminated water contamination concerns, while requiring only one greasing per 24-hour shift.

Since using LE for over 10 years, we have a lot of faith in your grease’s ability to hold up to extremes of heat, moisture and load.

- The Maintenance Manager

Customer Profile

This Lubrication Engineers customer is the largest independent box producer in the southeast. They operate four manufacturing locations in three states. They provide custom packaging in multi-color formats. They have been in business 19 years and an LE customer for more than 10.

Application

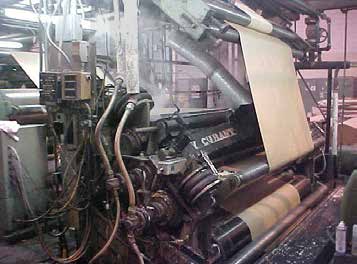

This company uses a Peters Corrugator to corrugate cardboard for the manufacturing of boxes. This unit has 360˚-380˚F (182°-193°C) superheated steam passing through the journals of these 12” tapered roller bearings.

Challenge

This unit was experiencing high amperage and the cost to lubricate the corrugator’s tapered roller bearings was more than $120 per pound of lubricant. Another concern was the problems occurring from water contamination on the glue rolls.

LE Solution

Almaplex® Ultra-Syn Lubricant (1299) was first employed for use on the corrugator’s pre-heat rolls. Due to the success of the product, it was installed on the corrugator tapered roller bearings. Almaplex 1299 is a full synthetic, specially formulated Aluminum Complex grease. It is made with a special blend of 100% synthetic base fluids optimized for the ISO 460 viscosity grade range for excellent performance under extreme equipment operating conditions. It also contains Almasol®, LE’s exclusive wear-reducing additive.

Almatek® General Purpose Lubricant (1232) is used for all cold bearings on the converting end of the process.

Results

The customer noticed the amperage decrease on this unit after the conversion to Almaplex 1299. Since it stays in place, less lubricant is needed therefore dropping their overall lubricant costs approximately 30%. Running a 24 hour shift, they grease one time using 8-10 shots per bearing. Since Almaplex 1299 was already being utilized in this plant there are less lubricants to stock. Almaplex 1299 has also eliminated the concern with the glue rolls. It keeps water out so there is no worry for water contamination.