Monolec® Multiplex Lubricant 4622

Item # 4622-TUBE — Monolec® Multiplex Lubricant 4622

High-Quality Grease Offers Versatile EP Performance

Monolec® Multiplex Lubricant (4622) is a highly versatile, longlife, lithium-complex-thickened grease designed for extreme pressure performance and extended relubrication intervals in a variety of industrial, marine, farm and fleet applications. It contains Monolec®, LE’s proprietary wear-reducing additive, and provides dependable performance in a broad operating temperature range in critical grease points including chassis and wheel bearings. Its versatility makes it possible to consolidate the number of greases used, especially helpful aboard a marine vessel.

If you cannot find the lubricant or product you need, please let us know what your requirements are by contacting us.

For a more detailed quote, choose similar products and add them to your Quote Cart. You will be able to provide additional project details in Quote Cart Checkout.

Asset Reliability Solutions

Available Container Size

Single Tube

Available Grades

NLGI 2

Texture

Smooth

Thickener Type

Lithium Complex

Asset Reliability Solutions

Beneficial Qualities

Demonstrates Excellent Versatility

- Works in wide variety of industrial, marine, farm and fleet applications

- Protects both plain and anti-friction bearings

- Meets requirements of NLGI GC-LB grease specification

- Demonstrates superior EP characteristics

- Has a Timken OK Load of 27.2 kg (60 lb)

- Provides exceptional film strength and protection against wear

- Protects against corrosion, rust and oxidation

- Exhibits long-lasting mechanical stability

- Results in minimal change in consistency even after repetitive shear

- Performs well in a broad temperature range

- Demonstrates excellent pumpability for cold weather applications

- Resists high temperatures and protects equipment in elevated temperature applications

- Exhibits high dropping point

Performance Requirements Met or Exceeded

- ASTM D4950

- NLGI GC-LB

- SAE J-310

Proprietary Additives

LE's proprietary additives are used exclusively in LE lubricants. Monolec Multiplex Lubricant contains Monolec.

Monolec® wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. An invaluable component in LE's engine oils, industrial oils andmany of its other lubricants, Monolec allows opposing surfaces to slide by one another, greatly reducing friction, heatand wear.

Typical Applications

- Industrial and marine: Conveyors, electric motors, fans

- Marine: Bearings, mooring and anchor winches, hose-handling and provision cranes

- Farm and fleet: Debarkers, ditching machines, dump trucks, forklifts, front-end loaders, vehicle fleets

Color

Red

NLGI Grade

2

Elastomer Compatibility (ASTM D4289)

CR Elastomer Hardness Change - Pass

CR Elastomer Volume Change - Pass

NBR-L Elastomer Volume Change - Pass

NBR-L Hardness Change - Pass

Four-Ball EP Weld Point kgf, ASTM D2596

400

Four-Ball Wear @ 75oC, 1,200 rpm, 40 kgf, 60 minutes, mm wear, ASTM D2266

0.59

Fretting Wear Protection, mg Loss (ASTM D4170)

7 mg

High Temperature Life hrs, ASTM D3527

100.3

Leakage Tendencies g, ASTM D4290

6

Low Temp Torque NM, ASTM D4693

14.5

Oil Separation 24 hrs @ 25oC, 1.75 kPa (0.25 psi), % Bleed, ASTM D1742

3.1

Timken OK Load lbs, ASTM D2509

60

Viscosity @ 100°C, cSt, ASTM D445

12.00

Viscosity @ 40°C, cSt, ASTM D445

129.4

Worked 100K Penetration ASTM D217

+43, +15.5%

Worked 10K Penetration ASTM D217

+22, +7.9%

Downloads

Popular Product Categories

Industrial Greases

Engine Oils

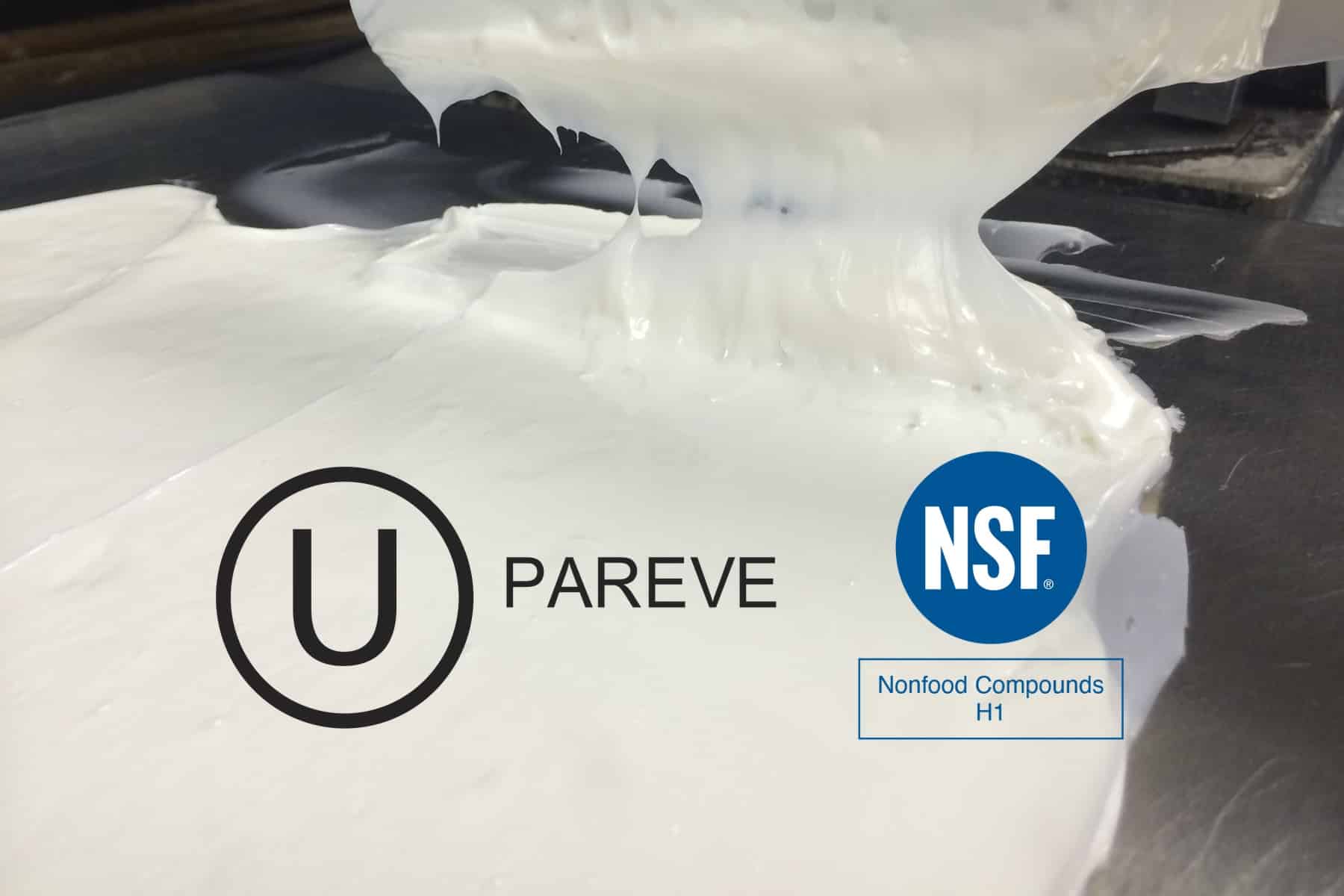

Food Grade Lubricants

Aerosol Lubricants

Gear Oils

Reliability Solutions

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A