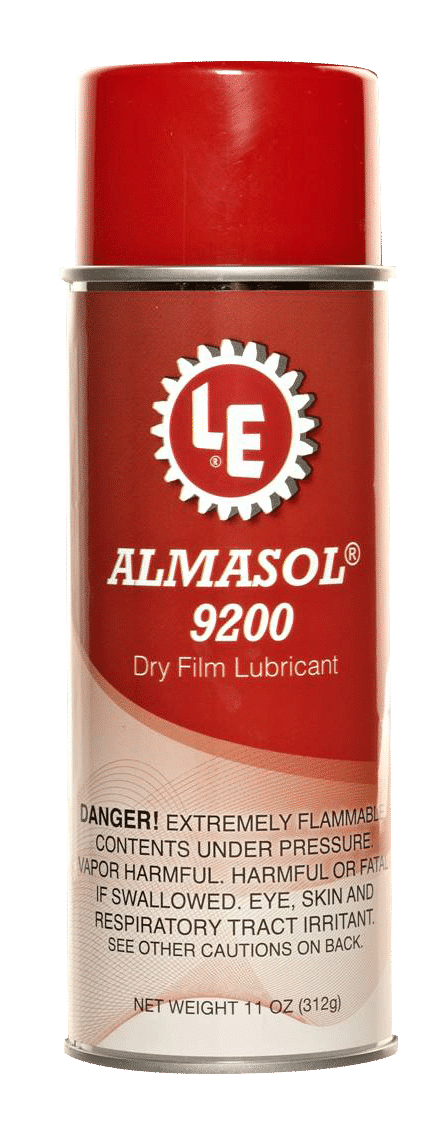

Almasol® Dry Film Lubricant 9200

Item # 9200-CSA — Almasol® Dry Film Lubricant 9200

Spray Lubricant Ensures Long-Lasting Lubrication in Tough Conditions & Broad Temperature Range

Almasol® Dry Film Lubricant (9200) is a solid film spray lubricant designed for use where permanent lubrication with exceptional long wear life and low frictional properties is desired, and oil and grease cannot be used. For use in a wide temperature range, it combines superior dry film lubrication with safe and easy spray application.

Almasol Dry Film Lubricant provides dependable, long-lasting lubrication in extreme environments where conventional lubricants would be inadequate. It contains a carefully selected blend of Almasol and other solid lubricants of controlled particle size, dispersed in a fast-drying solvent system and resin binder. The resulting film has excellent adhesion.

If you cannot find the lubricant or product you need, please let us know what your requirements are by contacting us.

For a more detailed quote, choose similar products and add them to your Quote Cart. You will be able to provide additional project details in Quote Cart Checkout.

Asset Reliability Solutions

Available Container Size

Case 12 Aerosols

Coverage per Can

2.8 sq m (30 sq ft)

Cure Time (air dry)

30 minutes to handle, 2 to 4 hours to use

Operating Temperature Range

-73 to 343°C (-100 to 650°F) [Up to 537°C (1,000°F) in absence of oxygen]

Shelf Life

12 months @ 20 to 26°C (68 to 78°F)

Asset Reliability Solutions

Beneficial Qualities

Wear & Friction

- Effectively lubricates surfaces where friction is aproblem, such as gears, actuators, cams, hinges, pins, shafts, tracks, threaded parts, frictional bearings, pistons, cylinders, valves and latches

- Prevents galling, seizing and fretting for splines, threaded connections and disconnects

- Protects mating metal surfaces under operating conditions of high loads and slow speeds

- Eliminates scoring by reducing the force required when disassembling parts for press fitting

- Performs in a variety of conditions:

- Broad temperature range:-73 to 343°C (-100 to 650°F)

- Dusty and abrasive environments

- Freshwater and saltwater

- Lasts two to five times longer than conventional dry film lubricants

- Possesses excellent EP properties, cannot be squeezed out up to 100,000 psi

- Lubricates effectively even after long periods of non-use

- Cures completely in two to four hoursat room temperature

- Comes in convenient, easy-to-use spraycan that contains no fluorocarbons

- Provides sufficient lubrication with a thinfilm; a small amount goes a long way

Proprietary Additive

LE's proprietary additives are used exclusively in LE lubricants. Almasol® Dry Film Lubricant contains Almasol. Almasol® solid wear-reducing additive is able to withstand extremely heavy ...

Recommendation

- Use with adequate ventilation; contains flammable solvents

- Store below 49°C (120°F)

- Do not store near heat, sparks or flame

Typical Applications

- Cams, Slides

- Chains

- Hinge Pins, Latches, Locks

- Metering Valves

- Sleeve & Pivot Bearings

- Spindles

- Threaded Parts

Color

Gray-Black

Recommended Coating Thickness (cured)

.005 to .01 mm (.0002 to .0005 in)

9200

0.070

Competitor A

0.059

Competitor B

0.080

Competitor C

0.080

Competitor D

0.077

Product Line

Initial Coefficient Of Friction:

Test Method for Bonded Solid Film Lubricant Coatings

The results of the test confirmed that Almasol 9200 lasts anywhere from two to five times longer than competitors' dry film lubricants that include PTFE, graphite or molybdenum disulfide. LE's exclusive Almasol solid additive has a higher load-carrying capacity and does not build uponitself as the other additives do.

Test Scope & Method This test method is used to determine the wear life and load-carrying capacity of bonded solid film lubricants by the Timken Test machine. The maximum wear life of the solid film lubricant applied to the surface of a rotating cup against a stationary block is determined along with the lubricant coefficient of friction

Procedure The spindle rotation speed is set to give a rubbing speed of 24-26 sliding feet per minute. After a break-in period of 30 seconds, a 10 lb. load is applied. Additional 10 lb. loads are applied after each 10 minute period for a total of 40-45 lbs. A coefficient of friction reading is taken 10 minutes after the last weight has been placed. Failure occurs when the coefficient of friction value is double the initial reading. The wear life is recorded as the number of revolutions to failure. Product Line Initial Coefficient Of Friction: Wear Life, Revolutions: Competitor A 0.059 90,000 Competitor B 0.080 200,000 Competitor C 0.080 200,000 Competitor D 0.077 250,000 9200 0.070 500,000

Testimonial Links

Downloads

Popular Product Categories

Industrial Greases

Engine Oils

Food Grade Lubricants

Aerosol Lubricants

Gear Oils

Reliability Solutions

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A