Xport® centralized automatic lube systems ensure fast, precise lubrication

A well-planned and executed centralized automatic lubrication system is a labor- and money-saving solution. It can save on the amount of lubricant used, eliminate downtime caused by improper lubrication, and can increase safety at your facility.

With the right system for your application, you can eliminate the inefficient hit-or-miss method of manual lubrication and the excessive costs of time-consuming lubrication routes and PMs.

Variety of automatic lubrication systems offer many benefits

Centralized auto lube systems are used in a broad array of industrial applications, such as mining, steel, paper, food & beverage, agriculture, packaging, and mobile on- and off-road equipment. Key to their popularity is that they improve the lubrication reliability practices of the organization while protecting the equipment.

Benefits of automatic lube systems include:

- Eliminating machine downtime associated with manual lubrication

- Reducing cross-contamination caused by lubricant mixing

- Eliminating the problems of overgreasing, undergreasing or not greasing at all

- Ensuring applications get precise amount of lubricant they need to operate efficiently at all times

- Improving safety by keeping maintenance operators away from hazardous areas or hard-to-reach lube points

- Eliminating lubricant-related housekeeping issues

Is centralized automatic lubrication the right solution?

If you have an application with multiple lubrication points, an automatic lubrication system can help improve the quality of the lubrication to the application, eliminating the safety hazards, time-intensive labor, and mistakes often made with manual lubrication.

If you’re unsure which automatic application method – single-point lubricators or centralized lubrication system – makes the most sense, Lubrication Engineers can help you determine which one best meets your needs. We can examine your situation and determine if a centralized automatic lubrication system is right for your organization. In many cases, the decision is easy because the calculations show an easy ROI to justify the new system.

One-stop shop for centralized lubrication systems & lubricants

Lubrication Engineers has the capability to help you plan, design and set up an automatic lubrication system in your facility. In addition to a line of preconfigured centralized lubrication systems, we also can help you with a wide variety of custom solutions.

LE makes it easy for us to find the right system for your operation. After selection, LE will provide a quote and can help you plan and install your entire system. We can help you plan the system from the ground up because we are available to be onsite to help ensure your automatic lubrication system meets your application-specific needs.

Even better, Lubrication Engineers can supply the right high-performance lubricant to go with the system and best protect your equipment. Think of us as your go-to source for your automatic lubrication system and lubricant needs, the perfect synergistic approach to solving your facility’s lubrication challenges.

Preconfigured automatic lubrication systems

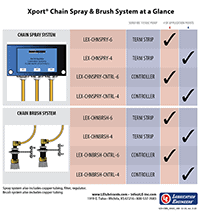

Xport Chain Spray/Brush System for oven chains

Designed for chain and hot oven chain applications, especially those in the food manufacturing industry, our Xport™ Chain Spray & Brush Systems deliver lubricant in either a spray or brush, ensuring consistent and reliable lubrication. The systems come with a variety of pump and application point options.

These preconfigured centralized lubrication systems from LE – together with LE’s specially formulated chain and hot oven chain lubricants – help manufacturing operations save time and money, and improve the protection of their critical assets.

- Xport Chain Spray System with Term Strip

- Xport Chain Spray System with Controller

- Xport Brush System with Term Strip

- Xport Brush System with Controller

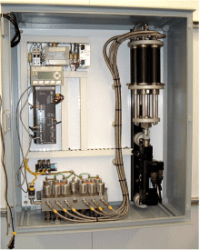

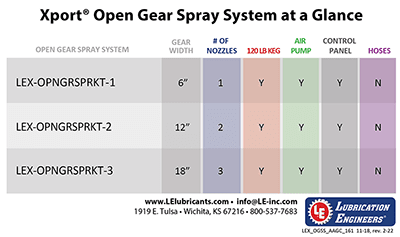

Xport Open Gear Spray Systems

Maximum protection for gear and pinion sets on ball mills and kilns, LE’s Xport™ Open Gear Spray Systems incorporate proven intermittent spray technology to reduce lubricant consumption while ensuring open gears are properly lubricated. These systems monitor both the lubricant and airflow to the nozzle tip, ensuring the right amount of lubricant is delivered at the right time. Using one of these systems to lubricate your open gears will create more operational uptime and reduce operating costs while extending gear and pinion life.

The Small Open Gear Spray Systems are for open gears less than 18 inches wide. The Large Open Gear Spray Systems are for open gears larger than 18 inches wide

Custom automatic lubrication systems

From planning down to final assembly, the LE team can help you design, plan and execute the centralized lubrication system that best meets your operation’s specific needs. Our versatile designs and the ability to tailor a system to your individual requirements enable us to ensure efficient performance.

LE’s expert installers make sure that the centralized lubrication system is integrated properly into your machinery and that the maintenance personnel at your facility are properly trained. The result is a reliable, long-lasting centralized lubrication system that provides a measurable return on investment. Contact us today to get started.